Commercial Laundry Hygiene 2025: Understanding the Science Behind Clean, Safe, and Odour-Free Linens (Extended Academic Edition)

Commercial Laundry Hygiene 2025 | Professional Linen Sanitisation London A Comprehensive Technical Guide for Hotels, Airbnb Hosts, Spas, Gyms & Medical Clinics

In the evolving hospitality, wellness, and clinical sectors, Commercial Laundry Hygiene 2025 represents a fully integrated scientific system—one that merges microbiology, chemistry, textile engineering, environmental science, and operational control. Linens may appear clean to the eye, yet they can still harbour bacteria, biofilms, oils, cosmetic residues, and odour compounds that compromise not only hygiene but also brand credibility and guest satisfaction.

As customer expectations continue to rise and regulatory standards tighten, businesses must understand the complete scientific framework underpinning professional laundry hygiene. This expanded guide provides deeper insight into how contamination persists despite washing, how professional systems achieve validated disinfection, and why specialised textile care is now essential for every business handling shared linens.

1. The New Hygiene Landscape: Why 2025 Raised the Standards

Since 2020, the global shift in hygiene awareness has reshaped customer behaviour and regulatory expectations in far more profound ways than most businesses initially anticipated. The pandemic fundamentally altered how individuals perceive cleanliness, shifting it from a routine operational task to a visible, measurable indicator of health protection and service credibility. Cleanliness is no longer viewed as a superficial aesthetic outcome; it now functions as a critical marker of environmental safety, professional discipline, regulatory compliance, and overall organisational integrity. For guests, patients, and clients, the condition of textiles has become a primary sensory cue signalling whether a business truly understands and upholds modern hygiene standards.

Since 2020, the global shift in hygiene awareness has reshaped customer behaviour and regulatory expectations in far more profound ways than most businesses initially anticipated. The pandemic fundamentally altered how individuals perceive cleanliness, shifting it from a routine operational task to a visible, measurable indicator of health protection and service credibility. Cleanliness is no longer viewed as a superficial aesthetic outcome; it now functions as a critical marker of environmental safety, professional discipline, regulatory compliance, and overall organisational integrity. For guests, patients, and clients, the condition of textiles has become a primary sensory cue signalling whether a business truly understands and upholds modern hygiene standards.

1.1 Higher Guest Sensitivity

Modern guests evaluate hygiene through a complex set of sensory and psychological signals—often without consciously recognising the depth of their own assessment. In hospitality science, this process is known as implicit hygiene perception, and it plays a far larger role in guest satisfaction than most businesses realise.

Guests form judgments based on subtle cues such as:

-

Faint mustiness that suggests early-stage microbial activity, even if linens appear freshly washed

-

Dense or oily towel textures, which indicate incomplete rinsing, detergent residue, or the presence of biofilm fragments

-

Bedding that feels limp or lacking structure, often resulting from fibre fatigue, mineral buildup from hard water, or accumulated body oils.

-

Robes that retain residual scents or oils signal repeated use without complete sanitisation.

These signals matter because humans subconsciously associate textile quality with environmental safety. When a towel feels heavy or slightly greasy, the brain interprets it as a hygiene risk—even if the guest cannot articulate the underlying cause.

Research in hospitality management, environmental psychology, and textile science consistently shows that guests use linen quality as a proxy indicator for overall property hygiene. When linens feel clean, crisp, soft, and neutral-smelling:

-

The guest perceives the entire room as cleaner

-

trust in the property increases

-

Comfort levels rise

-

The likelihood of a positive review significantly improves

Conversely, even minor textile issues—slight odour, texture changes, or visible dullness—can lower satisfaction scores and reduce return rates. In fact, multiple studies indicate that poor textile hygiene has a more substantial negative impact on guest perception than worn furniture or dated décor.

In summary, textile hygiene does not function in isolation; it directly shapes the guest’s psychological experience of the space. Clean linens communicate professionalism, safety, and operational excellence—values that modern travellers expect as standard.

1.2 Regulatory Pressure & Industry Standards

Across the UK and EU, businesses now face heightened expectations in:

-

validated thermal or chemical disinfection

-

controlled antibacterial and oxidation cycles

-

certified detergent and sanitiser use

-

documented cross-contamination procedures

-

safe handling, drying, and storage protocols

However, these bullet points only scratch the surface of what modern regulatory compliance currently demands. The regulatory framework governing textile hygiene has expanded significantly due to growing scientific evidence on the role of fabrics in disease transmission, allergen retention, and microbial persistence. As a result, regulatory bodies now emphasise evidence‑based validation, requiring businesses to prove—not merely claim—that their laundry processes consistently achieve microbiological safety.

For example, many facilities are now expected to implement:

-

Log-reduction targets, demonstrating measurable microbial kill rates comparable to clinical environments

-

Written hygiene assurance protocols, which show how each stage of textile handling—collection, sorting, washing, drying, finishing, and storage—is controlled

-

Regular audits and documentation reviews, ensuring that chemical dosing, wash temperatures, and disinfection cycles meet published standards

-

Traceability systems, allowing businesses to track each linen batch from soiling to sanitisation to delivery

-

Segregated workflow zones, preventing clean and soiled textiles from ever crossing paths

These requirements are based on NHS infection‑control principles, EU Textile Hygiene Directives, and evolving guidelines from the hospitality and wellness industries. What once counted as “clean enough” is no longer acceptable, especially in facilities where linens come into contact with skin, open pores, cosmetic treatments, sweat, bodily fluids, or medical environments.

Non-compliance not only risks hygiene failures but also legal liability—particularly for medical and wellness facilities, where textile contamination may contribute to infections, allergic reactions, or breaches of clinical safety standards. In some sectors, improper laundry hygiene can trigger regulatory penalties, failed inspections, insurance complications, or even temporary closure.

In short, regulatory expectations now push businesses beyond traditional cleaning routines, demanding scientifically validated hygiene systems that demonstrate reliability, traceability, and consistency at every stage of textile processing.

1.3 Modern Textiles Behave Differently

The hospitality industry increasingly relies on advanced performance textiles—materials engineered through modern fibre science to deliver durability, comfort, elasticity, absorbency control, and enhanced moisture‑management properties. These fabrics are far more complex than traditional cotton, and their behaviour during washing, drying, and contamination cycles is fundamentally different.

Unlike conventional natural fibres, performance textiles have specialised structures that:

-

Trap oils at a molecular level, particularly in polyester‑rich or microfibre blends, where hydrophobic fibre surfaces hold onto spa oils, sebum, massage balms, and lotions

-

Retain sweat acids and ammonia more effectively due to the binding affinity of synthetic polymers for acidic compounds produced during perspiration.

-

Support faster bacterial proliferation by trapping residues deep within the fibre matrix, which serve as fuel sources for microbial growth.

-

Require precise detergents, temperatures, and mechanical action, since standard home detergents cannot break down complex residues embedded within engineered fibres.

These textiles often include blends such as polyester‑cotton, elastane‑infused fabrics, microfibre weaves, and moisture‑wicking synthetics designed for athletic or spa environments. Each blend has unique properties that influence how contamination adheres, how easily odours develop, and how resistant the fabric becomes to traditional cleaning processes.

For example:

-

Microfibre towels, commonly used in spas and gyms, feature fine filaments that dramatically increase surface area, making them excellent for absorbency and ideal for trapping oils and bacteria.

-

Elastane‑containing fabrics, used in robes and fitted sheets, degrade when exposed to high heat, complicating thermal disinfection.

-

Polyester blends, popular in hotel linens due to durability, retain odour molecules more stubbornly than cotton because polyester is hydrophobic.

Traditional washing assumptions—higher heat equals cleaner textiles—do not reliably apply here. Many modern fabrics cannot tolerate high temperatures without damage, yet they still require deep‑level molecular cleaning to remove embedded oils, acids, and microbial biofilms.

This is why science‑based laundry systems are essential. They use:

-

Targeted enzyme combinations to dissolve oils, proteins, and biofilms

-

Oxygen‑based sanitisers to break down resistant odour molecules

-

Calibrated mechanical action to avoid fibre damage

-

Controlled pH environments to improve residue removal

Without these scientific processes, performance textiles degrade faster, retain odours longer, and pose greater hygienic risks—ultimately affecting guest satisfaction, regulatory compliance, and operational efficiency.

2. Understanding Contamination: How Bacteria & Odours Survive Washing

Microbial survival in textiles is influenced by environmental conditions, fibre structure, chemical interactions, and washing variables. Even visually clean linen may contain contamination invisible to the naked eye. This occurs because textiles are porous, absorbent surfaces rather than smooth ones. The spaces between fibres, the micro-grooves of synthetic textiles, and the hydrophobic nature of modern fabric blends all create ideal environments for microbial persistence.

Contamination is not just about the presence of bacteria—it involves complex biological processes such as microbial adhesion, chemical bonding of odour molecules, biofilm formation, and reactivation of residues when exposed to humidity. Each of these processes helps explain why some linens smell or feel unclean even after washing.

2.1 Biofilms: The Protective Layer

Biofilms are structured microbial communities encased in protective extracellular polymeric substances (EPS). These EPS layers act as a physical and chemical shield, allowing bacteria to survive washing, resist detergents, and bypass typical household sanitisation.

When biofilms attach to fibres, they:

-

Prevent detergents from penetrating deeply into textile structures

-

Shield bacteria from heat, oxidation, and pH changes

-

Retain organic residues (oils, sweat, proteins) that bacteria feed on

-

Enable recolonisation shortly after drying, as soon as humidity returns

The EPS layer behaves like a biological glue, adhering to cotton, polyester, and microfibre textiles. Because biofilms often anchor themselves in microscopic grooves on fibres, they are difficult to remove without specialised enzymatic and oxidising treatments.

Furthermore, biofilms often contain mixed-species microbial colonies, meaning several types of bacteria can live together and reinforce each other’s resistance. This enhanced resilience allows the community to survive conditions that would usually kill single bacteria.

Scientific research shows biofilms can:

-

Survive multiple domestic wash cycles at 30–40°C

-

Resist standard detergents due to EPS protection

-

Regrow rapidly when exposed to moisture or body heat

-

Continue releasing odour compounds long after washing

As a result, towels and sheets may appear visually clean but still harbour biofilm that contributes to persistent odours, a rough texture, and an increased risk of contamination. Only professional laundry systems—using enzyme blends and oxygen-based sanitisers—can reliably disrupt and remove biofilms at scale.

2.2 Odour Molecules Are Chemically Persistent

Odour arises not from sweat itself but from bacterial metabolism, meaning bacteria chemically transform components of sweat into highly potent molecules known as volatile fatty acids (VFAs). These VFAs—including isovaleric acid, butyric acid, and propionic acid—are the trustworthy source of unpleasant textile odours. Their behaviour in textiles is far more complex than most people realise.

Once created, these VFAs:

-

Bind tightly to cellulose and synthetic fibres through hydrophobic interactions and electrostatic attraction

-

Embed themselves deep within modern textile matrices, especially in polyester and microfibre blends

-

Resists breakdown at standard domestic washing temperatures, remaining chemically stable even after multiple washes

-

Reactivate instantly in the presence of humidity, which is why freshly washed towels can begin to smell sour within hours if not dried properly.

Why These Molecules Are So Difficult to Remove

VFAs have unique molecular structures that make them both volatile (meaning they evaporate easily and produce strong smells) and hydrophobic (meaning they resist water). This combination allows them to cling stubbornly to fabric fibres. Even when a towel or bedsheet smells clean immediately after laundering, VFAs can remain dormant within the fibres.

When the fabric encounters humidity—such as a warm bathroom, a damp environment, or skin contact—these molecules become volatile again and release their odour. This is why:

-

A towel smells fine when dry, but sour when used

-

Gym towels develop unpleasant smells shortly after workouts

-

spa towels emit rancid or metallic notes despite frequent washing

The Role of Sweat Chemistry

Human sweat contains a diverse mixture of biological and chemical compounds that directly influence how bacteria behave on textiles. Each component plays a unique role in how odours form, how bacteria metabolise nutrients, and how deeply residues bind into fabric fibres.

-

Amino acids — These serve as key nutrient sources for skin‑associated bacteria such as Staphylococcus epidermidis and Corynebacterium species. When metabolised, they produce volatile fatty acids (VFAs), ammonia derivatives, and sulphur‑containing compounds—all of which contribute to strong, persistent odours. Amino acids also enhance bacterial adhesion to fibres, accelerating biofilm formation.

-

Lactic acid — This acidic compound lowers the pH on textile surfaces, creating an environment where specific odour‑producing bacteria thrive. Lactic acid is particularly reactive with polyester and microfibre textiles, where it bonds readily and contributes to the “sour towel” effect as humidity rises.

-

Urea — Though odourless on its own, urea breaks down into ammonia through bacterial enzymatic activity (urease). Ammonia increases alkalinity, destabilises fibres over time, and creates a sharp, pungent smell commonly associated with gym towels and heavily used hospitality linens.

-

Salts — Sodium and chloride ions concentrate in sweat and accumulate in textiles, altering moisture‑retention behaviour. High salt levels create micro‑environments that attract and hold water, allowing bacteria to remain metabolically active longer. Salts also make the removal of oils and VFAs more difficult by reducing detergent efficiency.

-

Natural skin oils (sebum) — Sebum is one of the most challenging contaminants in laundry science. It contains triglycerides, fatty acids, squalene, and wax esters that bind tightly to hydrophobic fibres, such as polyester. When bacteria break down sebum, they create some of the most stubborn odour molecules in hospitality environments. Sebum also acts as a protective coating for bacteria, shielding them from detergents and heat, while helping biofilms anchor more securely to fibres.

In combination, these sweat components create a chemically rich environment that fuels microbial growth, odour formation, and textile degradation. Their complex interactions explain why sweat‑contaminated linens require targeted enzymes, oxidising agents, and controlled washing conditions to achieve proper hygienic cleanliness.

Bacteria consume these substances and metabolise them into VFAs. Different bacteria produce different odours, which is why gym towels, spa towels, and clinic linens each develop distinct scent profiles.

Why Home Washing Cannot Eliminate VFAs

Domestic washing machines typically rely on:

-

Low water temperatures (30–40°C)

-

Limited mechanical action

-

Mild detergents without specialised enzymes

These limitations make domestic machines fundamentally incapable of disrupting the chemical, biological, and physical mechanisms that keep VFAs attached to textile fibres.

1. Low Temperatures Cannot Break Chemical Bonds

VFAs are chemically stable at low temperatures. Domestic cycles rarely exceed 40°C, a range that:

-

Does not denature VFA molecules

-

Cannot dissolve the hydrophobic layers of sebum that protect bacteria

-

Allows biofilm fragments to remain fully intact

In contrast, professional laundries use controlled thermal phases or chemical disinfection to break down VFA molecules and the residues that shield them.

2. Limited Mechanical Action Fails to Dislodge Embedded Residues

Domestic machines have a gentle drum movement to protect clothing. However, this low agitation:

-

Cannot drive detergents deep into fibre structures

-

Fails to remove oils lodged in polyester and microfibre matrices

-

Leaves behind sweat residues that continue to fuel bacterial growth

Commercial machines apply calibrated mechanical energy (measured in G‑force and drum-rotation patterns) to break residue adhesion physically.

3. Mild Detergents Lack the Enzymes Needed for Molecular Breakdown

Household detergents contain very low concentrations of enzymes—if any at all—because they must be safe for a broad range of fabrics and skin sensitivities. Without specialised enzymes such as lipases, proteases, amylases, and cellulases:

-

Oils remain intact

-

Proteins stay bonded to fibres

-

Starches and cosmetic compounds persist

-

Biofilms remain protected by EPS layers

Professional detergents use industrial‑grade enzyme complexes designed to dismantle these residues at the molecular level.

4. Domestic Machines Use Too Little Water

Modern home washers, designed for water efficiency, often:

-

Reuse wash water within the cycle

-

Operate with low water‑to‑textile ratios

-

Produce inadequate flushing of residues

This means VFAs and sweat compounds are not rinsed away—they are redistributed across the textile surface.

5. No Controlled pH Environment

VFA removal requires precise control of alkalinity and acidity at different wash stages. Domestic machines cannot:

-

Adjust pH levels dynamically

-

Introduce neutralisation phases

-

Deliver staged chemical actions

Professional systems use pH‑programmed cycles that destabilise odour molecules and improve enzymatic performance.

6. Ineffective Spin Cycles Leave Too Much Moisture

Low‑G spin speeds in domestic washing machines:

-

Retain more moisture

-

Allow bacteria to reactivate sooner

-

Accelerate VFA volatility

Professional machines use high‑G extraction, removing moisture so quickly and thoroughly that bacteria have fewer opportunities to recolonise.

7. Domestic Dryers Cannot Guarantee Hygienic Drying Conditions

Incomplete or uneven drying allows VFAs to volatilise again and enables bacteria to repopulate fibres. Home dryers lack:

-

Airflow calibration

-

Controlled heat distribution

-

Moisture sensors with hygienic thresholds

This creates ideal conditions for “sour towel syndrome.”

Together, these limitations explain why home laundering cannot eliminate volatile fatty acids. The entire system—from water temperature to detergent chemistry to mechanical action—is insufficient to remove or neutralise the compounds responsible for persistent textile odours. Only professional laundry processes offer the precision, heat control, enzymatic action, and mechanical energy required to eliminate VFAs at their biochemical root.

These conditions are insufficient for breaking the chemical bonds between VFAs and textile fibres. Rather than being removed, VFAs are often redistributed, creating the illusion of cleanliness until humidity reactivates them.

Professional laundry systems use:

-

Targeted enzymes that break down sweat residues before VFAs form

-

Oxygen-based sanitisers that chemically neutralise VFA molecules

-

Controlled wash temperatures that destabilise odour compounds

-

High-G extraction that removes moisture—preventing VFA reactivation

This deeper, chemistry-driven approach is why professionally cleaned towels and linens remain fresh for much longer, even in humid environments.

In summary, unpleasant textile odours are not just a surface-level issue—they result from complex biochemical interactions among sweat, bacteria, and fabric fibres. Without the right chemistry and process control, these odours will always recur, regardless of how often the item is washed.

2.3 Cross-Contamination During Handling

Even if washing achieves complete sanitisation, contamination can easily return through improper handling—a critical issue often underestimated by businesses. In fact, many outbreaks of textile-related contamination in hospitality, wellness, and clinical settings are not caused by the washing process itself, but by what happens after washing.

Because freshly sanitised linens behave like “microbial magnets,” even a minor lapse can undo the entire hygiene process. The primary risk is recontamination, in which clean textiles come into contact with microbial reservoirs before reaching the guest or patient.

Key Cross-Contamination Risks

1. Collection Bins Carrying Microbial Load

Collection bins often remain damp and soiled for hours. This creates:

-

Ideal humidity conditions for bacteria and mould

-

Surfaces coated with biofilm residues

-

High microbial density that transfers easily onto any fabric placed inside

If these bins are not disinfected between uses, clean linens placed in them—even briefly—can pick up thousands of bacteria within seconds.

2. Sorting Tables with Biofilm Traces

Sorting tables frequently accumulate invisible layers of soil, oils, and microorganisms. Biofilms on these surfaces:

-

Allow pathogens to survive for days or weeks

-

Transfer onto clean textiles through simple contact

-

Resist many surface cleaners if not removed with the correct agents

Even a visually clean table can harbour microbial hotspots.

3. Transport Bags Not Sanitised Between Cycles

Transport bags are a significant vector for textile contamination. Without strict cleaning protocols, they:

-

Harbour bacteria from previous loads

-

Transfer spores, dust, and organic residues

-

Reintroduce odours and microbial aerosols into clean batches

Soft-sided bags are hazardous because their porous material traps moisture and biofilms.

4. Storage Shelves With Humidity Pockets

Improper storage environments allow clean linens to become contaminated through:

-

humidity-induced microbial growth

-

dust accumulation carrying microbial spores

-

air movement that deposits aerosolised contaminants

-

contact with improperly cleaned shelving surfaces

If humidity exceeds 60%, microbial proliferation accelerates dramatically, even on previously sanitised fabrics.

Why Handling Is One of the Highest-Risk Stages

Unlike washing—where chemicals, heat, and agitation ensure microbial reduction—handling environments are uncontrolled. Each touchpoint becomes an opportunity for:

-

Microbial transfer (direct contact)

-

Aerosol deposition (airborne contamination)

-

Biofilm seeding (surface-to-fabric adhesion)

Research shows that a single contaminated glove, surface, or airflow disruption can negate the entire sanitisation process.

How Professional Laundries Prevent Cross-Contamination

Professional laundries implement strict engineering controls and protocols, including:

-

Zoning systems that separate dirty, clean, and ultra-clean environments with no physical overlap

-

Positive airflow environments that push clean air outward, preventing dirty air from entering clean zones

-

Sterilised transport packaging, such as sealed bags or carts, is disinfected after every cycle

-

Colour-coded equipment to ensure tools used for soiled linens never contact clean textiles

-

Touchless conveyor systems that reduce human handling

These systems create a controlled pathway from soiled to sanitised linen, ensuring that once fabric is disinfected, it remains safe until delivery.

In essence, cross-contamination control is just as important as the washing process itself. Without rigorous handling protocols, even the best washing technology cannot deliver reliable hygiene outcomes.

3. The Science Behind Professional Disinfection Washing

Professional laundry systems apply advanced scientific principles to ensure measurable hygiene outcomes. These systems integrate mechanical force, temperature control, targeted chemistry, and time (the Sinner’s Circle model).

Professional laundry systems apply advanced scientific principles to ensure measurable hygiene outcomes. These systems integrate mechanical force, temperature control, targeted chemistry, and time (the Sinner’s Circle model).

3.1 Precision Washing Programs

Every textile category requires distinct wash parameters, and these parameters are not arbitrary—they are informed by textile engineering, soil chemistry, fibre physics, and microbiological risk assessments. Professional laundering relies on highly structured wash programming, where each variable is optimised to achieve measurable cleanliness and disinfection outcomes.

To achieve this level of precision, professional laundries use:

-

Programmable drum movement patterns that regulate mechanical action, ensuring fibres are flexed in ways that release embedded soils without causing structural damage. These patterns can be altered by textile type, soil load, and desired disinfection level.

-

Controlled water-to-textile ratios ensure adequate soil dilution and optimal detergent dispersion. Too little water traps soil; too much water weakens chemical efficiency. Professionals adjust ratios dynamically throughout the cycle.

-

Extended flushing cycles for cotton are essential because cotton fibres swell when wet, trapping soils deep within the fibre structure. Long flush cycles remove suspended particles, minerals, and chemical residues, preventing greying and fibre fatigue.

-

Reduced mechanical stress for synthetics, since polyester, elastane, and microfibre textiles require gentler agitation to avoid pilling, stretching, and surface abrasion. These fibres also trap oils more aggressively, requiring specialised agitation phases.

-

Calibrated dosing pumps for chemical accuracy, which deliver detergents, enzymes, alkalis, oxidisers, and pH-neutralisers in exact concentrations. Overdosing damages fibres; underdosing fails to remove soils or biofilms.

In advanced facilities, these parameters are continuously monitored by onboard sensors that analyse:

-

water turbidity (soil load)

-

pH levels at each phase

-

temperature stability

-

conductivity (detergent concentration)

-

drum torque (mechanical activity)

Such feedback systems allow the machine to adjust conditions in real time, ensuring consistent hygiene outcomes regardless of variations in soil levels or textile types.

Segregation prevents cross-contamination and ensures each textile receives the correct hygiene treatment. Professionals never mix cotton towels with microfibre, never wash heavily oiled spa linens with lightly soiled sheets, and never combine medical textiles with hospitality fabrics. This controlled segregation is essential to preventing redeposition, odour transfer, fibre damage, and microbial persistence.

3.2 Enzyme-Based Detergents

Enzymes are among the most critical components of Commercial Laundry Hygiene 2025, functioning as particular biological catalysts that accelerate the breakdown of organic soils without damaging fibres. Unlike traditional detergents that rely on surfactants and mechanical agitation alone, enzyme-based detergents target the molecular structure of contaminants, breaking them down in ways that are impossible for non‑enzymatic formulas.

At a scientific level, enzymes operate through the lock‑and‑key mechanism, meaning each enzyme binds to a specific soil type and breaks it down into smaller, soluble fragments that can be entirely removed during rinsing. This level of precision is essential for modern hospitality textiles, which retain oils, proteins, and starch residues far more stubbornly than older cotton-based fabrics.

The four primary enzyme groups include:

-

Proteases — break down proteins such as sweat, blood, skin cells, and microbial residues. These proteins act as both food sources for bacteria and structural anchors for biofilms. Removing proteins disrupts microbial colonisation and prevents odour formation.

-

Lipases — dissolve oils, lotions, massage balms, sunscreen, body creams, and spa treatment residues. Lipases are especially critical for spa towels and polyester-rich textiles, which trap oils deep within fibre matrices due to their hydrophobic nature.

-

Amylases — remove starch-based residues from cosmetics, skincare products, facial masks, and food spills. Starches harden during drying, making fibres feel rough and attracting bacteria that metabolise them into odour compounds.

-

Cellulases — gently modify cotton fibre surfaces by removing micro‑pills, restoring smoothness, enhancing brightness, and preventing greying. They also help release particles trapped between cotton fibrils.

Why Enzymes Are Essential for Modern Hospitality Textiles

Modern textiles, especially blends containing polyester, elastane, or microfibre, are engineered with hydrophobic surfaces that repel water but readily absorb oils and organic soils. Traditional detergents struggle to penetrate these fibres because water alone cannot dissolve oily residues.

Enzymes overcome this barrier by:

-

breaking soil molecules into smaller fragments that detach from fibres

-

degrading the organic matrix that supports bacterial growth

-

preventing re‑deposition of residues during the rinse cycle

-

enhancing the performance of oxidising agents used later in the wash

Because enzymes operate at lower temperatures, they also improve energy efficiency, preserve fabrics, and reduce textile damage, enabling professional laundries to achieve deeper cleaning without relying on extremely high heat.

Advanced Enzyme Blends Used in Professional Laundries

Professional detergents often contain synergistic enzyme cocktails, including:

-

multi‑protease systems for complex protein residues from sweat mixed with body creams or makeup

-

esterases for breaking down wax esters in sebum (a key contributor to stubborn odours)

-

mannanases for removing polysaccharides found in lotions, moisturisers, and food spills

-

pectinases for dissolving fruit‑based or plant‑derived soils common in spa environments

These specialised enzymes are rarely found in consumer detergents and are carefully dosed using automated injection systems to ensure consistent cleaning performance.

How Enzymes Improve Hygiene Outcomes

By eliminating organic residues at their molecular origin, enzymes:

-

deprive bacteria of their primary nutrient sources

-

disrupt the formation and adhesion of biofilms

-

reduce the biochemical pathways that lead to VFA (volatile fatty acid) odour generation

-

improve fabric softness and absorbency by removing microscopic buildup

In essence, enzyme-based detergents underpin professional laundry hygiene. Without them, even high temperatures and strong oxidisers cannot reliably remove complex residues from hospitality, spa, gym, and clinical textiles.

3.3 Oxidising Agents (Oxygen-Based Sanitisers)

Oxygen-based sanitisers are among the most potent tools in Commercial Laundry Hygiene 2025, delivering targeted microbial reduction through controlled oxidative reactions. These sanitisers typically include compounds such as peracetic acid, hydrogen peroxide, sodium percarbonate, and activated oxygen systems, all of which generate free radicals—highly reactive molecules capable of breaking apart organic contamination at a molecular level.

When released in the wash, these free radicals:

-

Oxidise microbial cell walls, disrupting membrane integrity and causing rapid cell death

-

Denature odour-generating molecules, including volatile fatty acids (VFAs) and the metabolic by-products of bacteria

-

Break apart residues shielded by biofilms, enabling enzymes and detergents to reach deeper contamination layers

-

Destroy pigments and organic soils, improving textile brightness and restoring whiteness

-

Provide sanitisation at lower temperatures, allowing delicate fabrics to be cleaned without thermal damage

Unlike chlorine-based sanitisers (which damage fibres, cause yellowing, and release harmful fumes), oxygen-based oxidisers are fabric-safe, environmentally compatible, and highly effective at penetrating modern textile structures. Their controlled oxidative pathways ensure substantial microbial reduction while protecting textile integrity.

How Oxygen-Based Systems Enhance Hygiene

Oxygen-based sanitisers are incredibly effective in environments with high contamination loads—such as spas, gyms, hotels, and clinics—because they:

-

work synergistically with enzymes, allowing deeper removal of complex soils

-

maintain efficacy across a range of pH levels, especially in alkaline main-wash phases

-

reduce the need for high-temperature thermal disinfection cycles

-

provide broad-spectrum action against bacteria, fungi, mould, and some viruses

Their ability to reach deep into fibre matrices makes them crucial for removing:

-

rancid spa oils

-

sweat acids and ammonia compounds

-

oxidised sebum residues

-

discolouration caused by biofilm accumulation

Oxygen-based sanitisers do not mask odours—they chemically break them down, which is why linens treated with them stay fresh for significantly longer.

3.4 Thermal Disinfection Protocols

Thermal disinfection is one of the oldest and most scientifically validated methods for ensuring textile hygiene. It relies on the principle that microorganisms—including bacteria, fungi, and some viruses—cannot survive sustained exposure to elevated temperatures.

Professional laundries follow strict, industry-recognised time–temperature disinfection curves, such as:

-

71°C maintained for a minimum of three minutes (NHS-recommended standard)

-

65°C maintained for at least ten minutes

These thresholds are not arbitrary—they are based on microbiology research showing the precise conditions required to achieve specific log reductions (levels of microbial kill). For example:

-

71°C for 3 minutes achieves approximately a 6-log reduction (99.9999% reduction)

-

Lower temperatures require proportionally more prolonged exposure to achieve the same microbial kill

Why Industrial Machines Are Essential

Unlike domestic machines, which fluctuate wildly in temperature (often by ±10°C), industrial machines:

-

Maintain constant temperatures throughout the disinfection phase

-

Monitor and document heat exposure for compliance

-

Ensure uniform heating across the entire load

Even a slight temperature drop—such as from 71°C to 65°C for just 30 seconds—can significantly reduce microbial kill effectiveness. This is why thermal disinfection must be precise, validated, and recorded.

When Thermal Disinfection Is Preferred

Thermal disinfection is especially effective for:

-

clinical linens

-

gym towels with high bacterial load

-

hotel sheets requiring consistent whiteness

-

fabrics that can withstand higher temperatures (100% cotton)

However, many modern textiles cannot tolerate extreme heat, making oxygen-based sanitisers essential alternatives.

3.5 High-G-Force Extraction

High-G-force extraction is one of the most overlooked components of commercial laundry hygiene, yet it plays a decisive role in preventing microbial regrowth and maintaining textile freshness.

Industrial washers typically operate at 350–450 G-force, compared to domestic machines that average 60–100 G-force. This difference is enormous and has significant implications for hygiene.

High extraction speeds remove up to 50% more water, resulting in:

-

significantly shorter drying times, reducing energy consumption

-

inhibition of microbial regrowth, since bacteria cannot multiply effectively on low-moisture surfaces

-

prevention of sour odour formation, which occurs when moisture reacts with residual sweat acids

-

improved fibre alignment, producing softer, fluffier, more luxurious-feeling towels

Why Low Extraction Causes Odour Problems

In-house laundry systems often rely on machines with inadequate spin force. These machines:

-

leave too much moisture trapped within fibres

-

create the perfect environment for bacteria to reactivate

-

promote the formation of volatile fatty acids as fabrics slowly dry

-

lead to stiff, heavy, or sour-smelling towels

Low extraction is one of the primary reasons hotels, spas, and gyms suffer from recurring odour issues—even when using acceptable detergents. Moisture is the catalyst for odour reactivation and microbial growth, making high-G extraction non-negotiable in any hygiene-driven laundry system.

Additional Benefits of High-G Extraction

Beyond hygiene, high-G extraction offers operational advantages:

-

Reduced dryer wear due to shorter cycles

-

extended textile lifespan thanks to gentler, faster drying

-

improved energy efficiency across the entire laundry process

In a properly calibrated commercial system, extraction is not merely a drying step—it is a critical hygiene control measure on par with chemical disinfection, enzyme activity, and thermal sanitation.

4. Drying: The Most Underestimated Step in Hygiene

Drying is not simply the final stage of laundry processing—it is a critical microbiological control point, on par with chemical disinfection, enzyme activity, and thermal sanitation. While washing removes soils and reduces microbial load, drying determines whether textiles remain hygienic or quickly become re‑colonised by bacteria, fungi, and odour‑producing microorganisms.

Drying is not simply the final stage of laundry processing—it is a critical microbiological control point, on par with chemical disinfection, enzyme activity, and thermal sanitation. While washing removes soils and reduces microbial load, drying determines whether textiles remain hygienic or quickly become re‑colonised by bacteria, fungi, and odour‑producing microorganisms.

Moisture is a biological catalyst. Even minimal water retention accelerates microbial metabolism, allowing surviving organisms to multiply rapidly, produce volatile fatty acids (VFAs), and create conditions that compromise both hygiene and fabric integrity. As a result, drying is often the decisive factor that separates clean, safe textiles from those that redevelop odours and contamination shortly after processing.

4.1 Moisture Creates Ideal Growth Conditions

Research in textile microbiology consistently shows that bacteria can resume growth within 20 minutes on damp fibres. This is due to the combination of:

-

retained water molecules that act as metabolic fuel

-

elevated textile temperatures after washing, which speeds microbial activity

-

oxygen penetration through porous fibres

-

nutrient residues (oils, proteins, salts) that remain even after washing

Professional drying systems counteract these risks by ensuring:

-

Uniform heat penetration, eliminating cold spots where microbes can survive

-

Total moisture removal, including from fibre cores where water is slow to evaporate

-

Disruption of microbial membranes, as rapid moisture loss damages cell structures

-

Prevention of mould and fungal germination, which requires sustained humidity to activate

-

Long-term freshness retention, since thoroughly dried textiles resist odour reactivation

In contrast, inadequate drying—widespread in in‑house laundry operations—leaves moisture pockets that act as microbial “hot zones,” enabling exponential bacterial growth.

4.2 The Physics of Freshness

Drying is not only a hygiene process but also a textile‑engineering function. During tumble drying, fibres are exposed to mechanical energy, heat, and airflow, which together restore textile loft and remove residues.

Proper drying achieves:

-

Fibre expansion, which opens internal channels and releases deeply embedded particles

-

Enhanced airflow between fibres, improving absorbency and softness

-

Restoration of the towel loft, creating the fluffy, luxurious feel expected in hospitality settings

-

Improved capillary action, enabling towels to absorb water more efficiently during guest use

-

Removal of microscopic debris, reducing the substrate available for microbial regrowth

Improper drying has the opposite effect. Compressed fibres:

-

trap moisture and residues

-

feel heavy, stiff, or matted

-

reduce absorbency due to collapsed fibre channels

-

accelerate odour formation because moisture cannot escape

-

shorten the textile lifespan by increasing mechanical fatigue

4.3 Anti-Mould Measures

Mould spores are highly resilient and can survive for extended periods in a dormant state. However, mould requires three conditions to activate: moisture, warmth, and organic nutrients. Laundry provides all three unless drying is executed correctly.

Commercial dryers prevent mould contamination by:

-

maintaining temperatures above fungal survival thresholds, ensuring spores cannot germinate

-

applying sustained airflow, which removes humidity faster than mould can utilise it

-

creating low-moisture final conditions, where water activity is too low for fungal metabolism

-

preventing condensation inside drums, a common issue in domestic dryers that promotes spore growth

This level of control protects against:

-

mildew scent formation, often caused by spores metabolising remaining sweat residues

-

fungal contamination, which can pose dermatological risks to guests

-

airborne spore exposure, a concern especially in clinics, spas, and wellness facilities

4.4 Why Drying Failure Is the #1 Cause of Odour Recurrence

Even if washing neutralises bacteria, improperly dried textiles will:

-

reactivate dormant odour molecules when humidity increases

-

allow residual bacteria to multiply rapidly

-

develop sour, metallic, or musty scents within hours

-

experience fibre degradation due to the enzymatic by-products of microbial activity

This is why drying must be understood as a core hygiene pillar, not merely an operational necessity.

4.5 Professional vs Domestic Drying: A Scientific Comparison

| Factor | Professional Dryers | Domestic Dryers |

|---|---|---|

| Heat Stability | Precise, consistent | Fluctuating temperatures |

| Airflow | High-volume, directional | Low, inconsistent |

| Moisture Sensors | Hygienic thresholds | Basic humidity detection |

| Anti-Mould Control | Yes | Limited |

| Drying Uniformity | High | Low (cold spots common) |

| Hygiene Outcome | Long-lasting freshness | Rapid odour return |

Professional dryers are engineered for microbiological safety, while domestic dryers are designed for convenience—not hygiene.

In summary, drying is a scientifically critical stage of professional laundry hygiene. It determines whether linens remain fresh, safe, and microbially stable—or whether they become rapidly re‑contaminated. In hospitality, spa, gym, and clinical environments, superior drying is non‑negotiable for maintaining hygiene, guest satisfaction, and textile longevity.

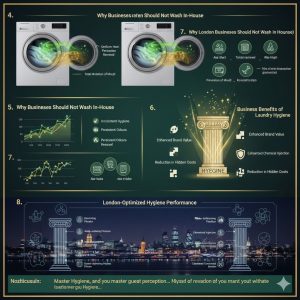

5. Why Businesses Should Not Wash In-House

In-house laundry setups often lack the controlled scientific environment required for consistent, verifiable sanitisation. Unlike professional systems—which rely on calibrated chemistry, thermal validation, engineered airflow, precise mechanical action, and contamination‑free workflows—on‑site laundry operations in hotels, spas, gyms, and clinics typically operate with domestic‑grade or semi‑commercial equipment designed for convenience, not hygiene.

As a result, in-house laundering often produces textiles that appear visually acceptable but fail to meet microbiological, chemical, and physical hygiene standards. The limitations extend beyond cleanliness, influencing textile lifespan, operational efficiency, customer perception, and long-term costs.

5.1 Inconsistent Hygiene

Domestic machines and compact commercial units cannot consistently regulate:

-

chemical dosing accuracy (leading to under- or over-washing)

-

thermal stability needed for microbial kill rates

-

Drum movement precision is required for soil release

-

Rinse cycles are essential for removing residues, minerals, and unreacted chemicals.

Why This Matters

Professional hygiene requires precision and repeatability. Even a slight deviation in temperature, pH, or detergent concentration can:

-

allow bacteria to survive

-

leave behind sweat acids that later become odours

-

contribute to biofilm formation within the textile

Domestic systems lack the engineering tolerances and chemical-injection systems required to meet hospitality‑grade hygiene standards.

Inconsistent hygiene results in:

-

hidden microbial loads

-

recurring odour problems

-

dinginess or greying of linens

-

increased guest complaints related to “cleanliness.”

5.2 Persistent Odours

Lower extraction forces and inconsistent drying allow:

-

sour towel syndrome (caused by moisture + VFAs)

-

Recurring musty odours triggered by humidity

-

trapped sweat acids that re‑activate when towels are used

The Science Behind the Problem

When inadequate extraction leaves moisture in the fibres, bacteria can resume metabolic activity almost immediately. This creates:

-

volatile fatty acids (VFAs)

-

ammonia compounds

-

rancid-smelling breakdown products from spa oils and sebum

Domestic or small-commercial systems cannot achieve the low‑moisture conditions required to suppress microbial regrowth. Professional laundries use 300–450 G‑force extraction and calibrated drying systems to eliminate this risk.

5.3 Reduced Linen Lifespan

Improper care leads to:

-

fibre degradation from unregulated heat exposure

-

shrinkage and stretching due to incorrect mechanical action

-

early thinning and tearing from chemical imbalance or over‑processing

-

colour loss and dulling due to mineral deposits and poor rinsing

Financial Impact

Textiles represent a high recurring cost for hospitality and wellness businesses. When processed incorrectly:

-

Linen’s lifespan decreases by 30–50%

-

Replacement cycles shorten dramatically

-

Overall operational costs rise

Professional systems extend textile lifespan by up to 40%, mainly due to:

-

balanced washing mechanics

-

accurate pH control

-

controlled water hardness treatment

-

enzyme‑based soil removal that reduces fibre stress

5.4 Reduced Customer Confidence

Guests evaluate hygiene subconsciously through tactile and olfactory cues. Poor textile quality directly weakens:

-

guest satisfaction

-

brand reputation

-

online reviews

-

repeat bookings

Why Textiles Influence Trust

Human perception heavily relies on touch and smell. When a towel feels rough, heavy, or slightly damp—or carries even a faint odour—the guest interprets the entire environment as less hygienic. Research consistently shows that linen quality is one of the strongest predictors of overall cleanliness ratings.

Even if a room is spotless, poorly laundered textiles can:

-

trigger negative reviews

-

decrease perceived value

-

reduce the likelihood of return visits

In an era where guests are more hygiene-conscious than ever, inconsistent in-house laundry performance can undermine a business’s credibility.

The Core Problem: In-House Laundry Is Built for Convenience, Not Hygiene

Most on‑site laundry operations lack:

-

The chemical precision required for disinfection

-

The thermal validation needed for microbial kill

-

The necessary mechanical force for residue removal

-

The extraction power needed to prevent odour formation

-

The airflow engineering required for hygienic drying

-

The essential controls to protect clean linen from contamination

Professional laundries solve these issues with:

-

automated chemical injection systems

-

calibrated wash formulas

-

validated disinfection processes

-

industrial extraction force

-

controlled drying environments

-

sterile or low‑microbe finishing areas

This is why businesses that outsource to hygiene‑focused professional laundries experience:

-

dramatically fewer odour complaints

-

higher guest satisfaction scores

-

longer textile lifespan

-

lower long-term operational costs

In short, in-house washing is rarely a cost-saving measure. Without scientific controls, it often becomes more expensive, less hygienic, and damaging to the brand over time.

6. Sector-Specific Hygiene Needs

6.1 Hotels & Airbnb Hosts

6.1 Hotels & Airbnb Hosts

Hotels and short‑stay accommodations experience constant textile turnover, making their linens some of the most frequently contaminated in the hospitality sector. Each guest introduces a unique mix of skin microbiota, cosmetic residues, and environmental pollutants, all of which accumulate on fabrics in ways that require targeted, scientifically validated hygiene processes.

Key Contamination Sources

-

Makeup pigments — Modern cosmetics contain silicones, oils, iron oxides, and long‑wear polymers that bond aggressively to fibres. These pigments require enzyme‑based and oxidising treatments for complete removal.

-

Skin oils and sebum — Sebum oxidises quickly on pillowcases and sheets, leading to yellowing, fibre stiffening, and persistent odours. Polyester blends retain these oils especially deeply.

-

Residual lotions, sunscreen, and self‑tanners — These products contain UV filters, zinc oxides, titanium dioxide, and emollients that clog textile pores, reduce brightness, and accelerate bacterial attachment.

-

Sweat compounds on pillowcases — Sweat acids, salts, and ammonia compounds bind to fibres and reactivate odours when guests lie down.

-

Damp towels left in enclosed bathrooms — Humidity + warmth = rapid microbial growth. Towels left on radiators or bathroom floors can harbour bacteria within 60–90 minutes.

The Hygiene Impact

Because these contaminants accumulate across multiple guests, hotels and Airbnbs face high risks of:

-

Cross‑guest microbial transfer

-

Visible dullness and yellowing of linen

-

Recurring pillowcase odours (“sour pillow effect”)

-

Reduced textile softness and absorbency

-

Poor guest reviews are tied directly to perceived cleanliness

Professional laundries counter these issues by using:

-

Multi‑enzyme detergents for cosmetic + body-fluid residues

-

Oxygen‑based sanitisers to break down odour molecules

-

Complex water correction to prevent greying

-

High‑G extraction for faster drying and odour prevention

-

Controlled pH systems to restore textile brightness and softness

Together, these processes extend linen life, improve whiteness, enhance softness, and restore the “hotel‑fresh” tactile experience guests expect.

6.2 Spas & Wellness Centres

Spa linens face some of the most difficult soils in the textile industry due to constant exposure to oils, balms, exfoliants, and cosmetic formulations. Many of these substances oxidise, chemically polymerise, or harden within fibres when not properly removed.

Why Spa Oils Are So Damaging

Typical contamination includes:

-

Massage oils (natural + synthetic blends) — Contain triglycerides and essential oils that oxidise, turning rancid and producing strong, sour odours.

-

Aromatherapy oils — Many are plant‑based and create sticky residues that trap bacteria.

-

Body balms and waxes — Harden inside towel loops, reducing absorbency and increasing stiffness.

-

Exfoliant particles — Interlock with cotton loops and cause abrasion during washing.

When spa oils oxidise, they create:

-

Rancid smells

-

Permanent discolouration

-

Fibre weakening due to chemical breakdown

Required Professional Treatment

Only a combination of enzymatic breakdown (lipases + proteases) followed by oxygen‑based oxidation can:

-

Dissolve hardened oils

-

Remove embedded aromatic compounds

-

Eliminate rancid odours

-

Prevent long‑term yellowing of spa towels and robes

Professional laundries also use:

-

Segmented wash programs to prevent oil transfer to other textiles

-

High‑G extraction to prevent re‑oxidation during slow drying

-

PH‑controlled rinsing to preserve towel softness

This scientific approach protects expensive spa textiles, maintains client comfort, and ensures regulatory compliance with hygiene standards.

6.3 Gyms & Fitness Studios

Gym textiles pose a unique microbiological challenge due to elevated sweat levels, high salt concentrations, and high bacterial diversity on athletic skin.

Key Contaminants

Gym linens contain high concentrations of:

-

Sweat bacteria — including Corynebacterium, Staphylococcus, and Micrococcus species, all of which produce strong VFAs.

-

Salts — trap moisture, keeping fibres damp and enabling bacterial metabolism.

-

Ammonia + urea compounds — contribute to sharp, pungent odours.

Additional Gym‑Specific Risks

-

Fungal pathogens (e.g., dermatophytes) thrive in damp towels.

-

High humidity from locker rooms accelerates microbial growth.

-

Rapid textile turnover means contamination accumulates quickly.

Required Hygiene Controls

Reliable gym‑linen sanitation requires:

-

High‑temperature disinfection phases to kill sweat bacteria,

-

oxygen‑based sanitisers to eliminate deep-set odours

-

Enzyme blends to break down sweat residues

-

High extraction speeds to prevent moisture retention

Without these controls, gym towels develop:

-

Persistent “locker-room smell.”

-

stiff texture from salt + sweat buildup

-

fungal contamination risks for users

Professional laundry systems restore softness, prevent microbial transfer, and protect gym-goers from dermatological pathogens.

6.4 Medical Clinics & Aesthetic Practices

Clinical and aesthetic environments require near‑sterile textile processing, as linens can come into contact with broken skin, open pores, medical devices, and potential biohazards.

Required Hygiene Standards

These facilities must meet:

-

Validated sanitisation levels (log reductions) — guaranteeing microbiological kill rates equivalent to healthcare protocols.

-

Sterile or low‑microbial handling zones — eliminating exposure to airborne or surface contaminants during folding and packing.

-

Sealed packaging with full traceability — ensuring that each batch can be linked to its wash cycle, disinfection parameters, and handling pathway.

-

Cross-contamination barriers — preventing medical linens from coming into contact with hospitality textiles or general spa laundry.

Why This Matters

Improperly sanitised clinical textiles can lead to:

-

increased infection risks

-

allergic reactions from residual chemical or microbial contaminants

-

breaches of health‑care compliance

-

failed audits or regulatory penalties

Professional laundry systems deliver clinical‑grade linen hygiene through:

-

Documented thermal or chemical disinfection

-

Strict zoning and airflow control

-

Sterile packing rooms

-

Batch traceability for compliance audits

This ensures both patient safety and alignment with modern healthcare regulations.

—.

7. Business Benefits of Professional Laundry Hygiene

Businesses adopting Commercial Laundry Hygiene 2025 achieve measurable improvements across operational, financial, hygienic, and reputational dimensions. These gains are not accidental—they reflect the compound effect of science‑driven laundering, consistent process control, and the elimination of variables that typically undermine textile hygiene.

Businesses adopting Commercial Laundry Hygiene 2025 achieve measurable improvements across operational, financial, hygienic, and reputational dimensions. These gains are not accidental—they reflect the compound effect of science‑driven laundering, consistent process control, and the elimination of variables that typically undermine textile hygiene.

Quantifiable Operational & Hygiene Benefits

-

35–60% reduction in odour-related complaints — achieved by eliminating volatile fatty acids (VFAs), biofilm fragments, and moisture pockets that drive sour-towel syndrome.

-

~40% extension of linen lifespan — due to balanced pH, controlled mechanical action, and reduced fibre fatigue from over‑processing.

-

Higher guest satisfaction and review scores — because linen quality directly influences perceived cleanliness, comfort, and overall trust in the environment.

-

Reduced onsite staff workload — as teams no longer battle recurring odours, rewash cycles, or damp, heavy towels.

-

Improved compliance with hygiene standards — supported by validated disinfection cycles, documented processes, and traceable wash data.

-

Stronger overall brand reputation — elevated by consistently crisp, soft, neutral-smelling linens that subconsciously signal professionalism.

-

Fewer textile replacements each quarter — lowering long-term capital expenditure and stabilising operational budgets.

The Deeper Strategic Advantages

Beyond these measurable gains, businesses experience several strategic improvements that significantly elevate performance:

1. Predictable Hygiene Outcomes

Professional laundry eliminates the guesswork associated with in-house washing. With calibrated chemical dosing, thermal validation, moisture-controlled drying, and strict zoning, businesses receive predictable, repeatable, audit-ready hygiene outcomes every cycle.

2. Enhanced Brand Value

Clean, fresh linens are among the strongest sensory indicators of quality in hospitality, spa, fitness, and clinical environments, but their influence extends far deeper than most businesses realise. From a behavioural-science perspective, textile hygiene activates the brain’s environmental assessment mechanisms, shaping how guests evaluate safety, professionalism, and overall service standards within seconds of contact.

Guests subconsciously interpret linen quality as a proxy for:

-

Safety and microbiological cleanliness, assuming that fresh-feeling textiles reflect strong hygiene systems

-

Organisational discipline, because well-maintained linens imply consistent operational control

-

Attention to detail, signalling that the business cares about the small things guests often notice first

-

Overall cleanliness of the facility, as humans naturally generalise tactile cleanliness to the entire environment

-

Brand integrity, associating premium textile care with a premium service philosophy

This sensory and psychological response creates measurable commercial advantages, including a tangible uplift in:

-

Guest trust, as guests feel physically safer and more comfortable interacting with the space

-

Willingness to return, driven by emotional reassurance and comfort-based memory formation

-

Positive review frequency, since linens are among the most commonly mentioned indicators of perceived hygiene

-

Average daily rates (hotels), as properties with superior textile quality can justify higher price points

-

Treatment or membership retention (spas & gyms), because fresh, neutral-smelling towels elevate the entire wellness experience

-

Client compliance and comfort in clinical settings, where hygienic textiles reduce perceived medical risk

In essence, linen quality operates as a multisensory branding tool, shaping guest perception at both conscious and unconscious levels. Premium textile hygiene does not merely support the service experience—it becomes central to how the business is judged, remembered, and valued.

3. Reduction in Hidden Costs

In-house laundry appears cheaper on the surface, but hidden costs accumulate quickly—and often invisibly. What seems like a simple operational task spirals into a network of inefficiencies, accelerated textile damage, labour strain, and uncontrolled chemical usage. When viewed through a full cost-of-ownership lens, the financial burden of in-house laundry is far greater than most businesses anticipate.

Professional laundry reduces or eliminates:

-

Rewash cycles, which consume excess water, electricity, detergents, and staff time

-

Emergency linen replacements, often triggered by irreversible stains, odours, or fibre degradation

-

Staff overtime dedicated to laundry recoveries, especially during peak occupancy periods when in‑house systems cannot keep up

-

Chemical wastage from manual dosing, where human error leads to overuse, underuse, or incorrect chemical combinations

-

Premature wear caused by improper temperatures or pH levels, which shortens textile’s lifespan and forces more frequent reordering

-

Equipment maintenance and breakdown costs are increasingly familiar with domestic‑grade washers used beyond their design capacity.

-

Energy inefficiencies, since domestic or semi‑commercial machines lack the heat‑recovery, moisture‑control, and high‑G extraction features of professional systems

The Hidden Financial Drain

Many businesses are surprised to discover that in-house laundry introduces a cascade of secondary costs:

-

Higher utility bills due to long drying times and inefficient extraction

-

increased staff turnover, as laundry work is labour‑intensive and physically demanding

-

Reduced room turnover speed when housekeeping waits for slow wash cycles

-

Reputational costs tied to odour complaints or perceived lack of hygiene

-

space costs—valuable property used to house washers and dryers that could be monetised or repurposed

These indirect costs accumulate silently and consistently, eroding profit margins month after month.

Why Professional Laundry Delivers True Cost Efficiency

Professional laundries operate with:

-

Predictable, validated disinfection cycles

-

Automated chemical dosing, eliminating chemical waste

-

High‑efficiency extraction and drying, reducing energy consumption

-

Industrial‑grade equipment, engineered for longevity and performance

-

Expert textile handling, extending linen life and preventing costly damage

Over time, these advantages compound, enabling businesses to operate with:

-

lower textile replacement rates

-

fewer operational disruptions

-

reduced labour expenditure

-

improved utility efficiency

-

stronger guest satisfaction metrics

In many cases, the savings from an extended linen lifespan alone outweigh the total cost of outsourcing.

Over time, businesses consistently find that professional laundry systems offer far greater cost efficiency—even before accounting for improved guest satisfaction, stronger reviews, and enhanced brand perception.

4. Enhanced Staff Efficiency

When staff are freed from troubleshooting sour towels, manually sorting mixed soils, or managing inconsistent equipment, they can redirect their time toward higher-value tasks. In operational science, this reallocation of labour is known as task elevation—a shift from low‑value, repetitive, hygiene‑risk activities to functions that directly enhance revenue, guest satisfaction, and service delivery.

Examples of elevated staff contributions include:

-

Guest service, where employees can focus on hospitality interaction instead of laundry recovery

-

Treatment preparation, enabling spas and clinics to increase throughput and maintain calmer workflows

-

Clinic operations, where precision, timing, and cleanliness directly affect patient outcomes

-

Room turnover, allowing housekeeping teams to accelerate service without compromising quality

-

Facility maintenance, which is often neglected when teams are overloaded with laundry‑related tasks

Freed from the physical strain and time pressure of in‑house laundry troubleshooting, staff experience:

-

Reduced fatigue, as laundry work is one of the most labour‑intensive tasks in hospitality and wellness environments

-

Higher morale, due to more meaningful and less repetitive job responsibilities

-

Better task accuracy, since cognitive load decreases when workers are not interrupted by equipment failures or urgent rewashes

-

Enhanced productivity, because workflow interruptions decrease as textile quality stabilises

From an organisational perspective, this shift strengthens operational flow. Teams can maintain smoother service rhythms, meet peak‑demand periods more effectively, and uphold higher standards of guest or patient experience. In the long term, this contributes to lower staff turnover, improved workplace satisfaction, and stronger operational resilience.

5. Competitive Differentiation

In saturated markets like London, minor differences create significant competitive advantages. Businesses with consistently pristine linens:

-

stand out in reviews

-

command higher prices

-

experience fewer hygiene complaints

-

impress first-time visitors

-

differentiate themselves from competitors relying on outdated or inconsistent laundry setups

The Psychological Power of Premium Linens

High-quality linen is a subtle but potent marketing tool—one guests consistently remember, even if they cannot articulate the reason. From a cognitive science perspective, linens function as sensory anchors: small yet emotionally charged touchpoints that subtly shape how the overall experience is interpreted. Freshness, softness, temperature, and a neutral scent create micro-moments of comfort that activate the brain’s reward pathways and strongly shape a guest’s emotional impression of the business.

These sensory cues produce an immediate signal of order, care, and safety. Guests instinctively link the tactile experience of crisp, clean linen with broader assumptions about the organisation’s discipline and standards. When the textile feels luxurious and fresh, it communicates effort—and guests equate effort with quality.

This effect is most potent in:

-

Boutique hotels, where personalised luxury is expected, and linens serve as a defining marker of refinement

-

luxury Airbnbs, where linen quality often determines whether the property feels genuinely “premium” or merely well-photographed

-

Wellness spas, where fresh, soft towels reinforce the atmosphere of relaxation, purity, and therapeutic professionalism

-

Fitness studios, where hygienic linens counteract sweat-heavy environments and influence perceptions of cleanliness and safety

-

Aesthetic & medical clinics, where sterile-feeling, neutral-scented linens reduce patient anxiety and reinforce clinical credibility

Clean linens communicate far more than cleanliness. They signal:

-

Competence, suggesting the organisation is in control of its operations

-

Professionalism, showing attention to details that matter

-

Hygiene discipline, which is increasingly essential in post‑pandemic behaviour patterns

-

Luxury, through tactile and olfactory cues that elevate the perceived service tier

-

Trustworthiness, because guests equate fresh linens with safety and high standards

From a branding perspective, textile quality becomes a silent ambassador—a nonverbal communicator that reinforces the business’s identity without a single spoken word. In many environments, guests may forget the room layout or décor, but they remember how the linens felt. That memory shapes reviews, influences repeat bookings, and ultimately defines the emotional legacy of the visit.

8. Why London Businesses Choose Professional Linen Care

London presents unique laundry challenges due to a combination of environmental, infrastructural, and behavioural factors that make textile hygiene significantly more complex than in many other UK regions. These challenges are not merely operational inconveniences—they stem from quantifiable scientific conditions that directly influence microbial survival, fabric degradation, odour formation, and the long-term performance of hospitality textiles.

London presents unique laundry challenges due to a combination of environmental, infrastructural, and behavioural factors that make textile hygiene significantly more complex than in many other UK regions. These challenges are not merely operational inconveniences—they stem from quantifiable scientific conditions that directly influence microbial survival, fabric degradation, odour formation, and the long-term performance of hospitality textiles.

Why London’s Environment Is So Challenging

-

Extremely hard water causing mineral buildup — London’s water hardness often exceeds 250–300 ppm, among the highest in Europe. Calcium and magnesium ions bind to detergents, reducing their cleaning efficiency and allowing mineral films to accumulate on fibres. Over time, this leads to greyed towels, stiff textures, and reduced absorbency—conditions that trap oils and bacteria more easily.

-

High humidity promoting bacterial growth — London’s frequent rainfall and damp indoor environments create ideal conditions for microbial recolonisation. Wet towels and linens can develop biofilms or volatile fatty acids (VFAs) within 20–40 minutes if not dried properly.

-

Rapid turnover of hospitality guests — Hotels, Airbnbs, serviced apartments, and spas in London experience some of the fastest guest turnover rates in Europe. This increases contamination loads and requires more frequent disinfection than typical regional operations.

-

Dense urban environments increase the risk of textile contamination — pollution particles, skin microbiota, cosmetic residues, and airborne oils accumulate more quickly in metropolitan areas. These contaminants embed into fibres and require targeted chemical and mechanical removal.

How Professional Laundries Solve These Issues Scientifically

-

Water-softening filtration systems — By removing hardness minerals before washing, these systems allow detergents to perform at full efficiency. This improves chemical penetration, reduces greying, restores softness, and prevents mineral crusts that trap bacteria.

-

Calibrated chemical injection pumps — London’s diverse contamination profiles require exact chemical dosing. Automated pumps deliver enzymes, alkalis, sanitisers, and pH-corrective agents with laboratory precision—far beyond manual dosing used in most in-house systems.

-

Moisture sensors ensure precise drying by detecting water content deep within the textile core, not just on the surface. This prevents under-drying (which causes odours and microbial regrowth) and over-drying (which damages fibres and reduces lifespan).

-

Sterile packing rooms that prevent recontamination — In a dense city where airborne contaminants are abundant, professional laundries use positive-pressure clean zones, HEPA filtration, and surface-sterile environments to maintain hygiene after disinfection is complete.

The Result: London-Optimised Hygiene Performance

When these advanced systems work together, businesses receive linens that remain:

-

Bright, due to mineral-free washing environments

-

Soft, due to fibre-preserving chemical and mechanical control

-

Fresh, thanks to complete odour molecule neutralisation

-

Clinically hygienic, with validated microbial reduction even in high-risk sectors like spas and clinics

Professional laundry isn’t just beneficial in London—it is necessary for any business that wants to maintain hygiene, protect textile investments, and consistently meet guest expectations in one of the world’s most demanding urban environments.

Conclusion: Hygiene as the Foundation of Modern Operational Excellence

In 2025 and beyond, Commercial Laundry Hygiene is no longer a background operational task—it is the structural backbone of every high-performing hospitality, wellness, fitness, and clinical business. The science is precise: textiles are living environments. They absorb sweat chemistry, trap oils, harbour bacteria, bind odour molecules, and accumulate residues that cannot be removed through outdated or domestic laundering methods.

Modern expectations demand modern solutions. Guests and clients now evaluate hygiene with heightened sensitivity, relying on subtle tactile and olfactory cues to judge whether a business is safe, professional, and trustworthy. A single sour towel, a slightly musty sheet, or a robe that feels oily can undo thousands of pounds of investment in décor, marketing, or customer service. Cleanliness is no longer visual—it is biochemical, and guests instinctively know the difference.

Professional Commercial Laundry Hygiene 2025 resolves these challenges through:

-

Validated disinfection backed by microbiological science

-

Enzyme and oxidation chemistry capable of dismantling complex soils and odour molecules

-

Precision-controlled washing and drying environments that prevent recontamination

-

Textile-preserving processes that extend linen lifespan and protect capital investment

-

Strict cross-contamination controls ensure proper microbial safety from pickup to delivery