Linen Hygiene Risk London 2026: Why Hotels, Airbnbs & Spas Can No Longer Treat Laundry as a Back‑Office Task

Laundry Has Become a Business Risk

By 2026, linen hygiene risk in London will have moved well beyond whether sheets and towels look clean. Within London’s hospitality sector, laundry now represents a quantifiable operational risk that directly influences guest satisfaction, digital reputation, regulatory exposure, labour efficiency, and long‑term financial performance.

Hotels, Airbnbs, serviced apartments, and spas that continue to rely on in‑house or domestic‑style laundry systems often assume they are controlling costs. From a systems perspective, however, they are absorbing unmeasured risk. These risks only become visible when failures occur—guest complaints about odour, reports of skin irritation, negative reviews questioning cleanliness, or compliance inquiries that cannot be answered with documented process controls.

This pillar guide examines why linen hygiene now operates at the intersection of textile science, environmental conditions, regulatory accountability, and commercial economics—and why professional laundry has become a structural requirement rather than an operational convenience.

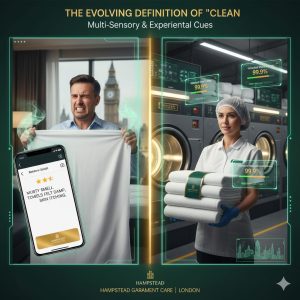

1. The Evolving Definition of “Clean” in Hospitality

Historically, cleanliness was assessed visually: white linen, neutral scent, no visible stains. In contemporary hospitality, this definition is no longer sufficient.

Historically, cleanliness was assessed visually: white linen, neutral scent, no visible stains. In contemporary hospitality, this definition is no longer sufficient.

Modern guests assess hygiene through multi‑sensory and experiential cues, including:

- Towels that appear clean but develop musty odours during use

- Sheets that feel stiff, damp, or coated due to chemical or moisture residue

- Linen that triggers itching or skin sensitivity

- Environments that look clean yet feel physiologically uncomfortable

From a behavioural standpoint, these signals are interpreted as hygiene failure rather than subjective preference. Once this perception forms, trust deteriorates rapidly, and negative reviews spread quickly across review platforms.

Understanding Linen Hygiene Risk: London- The Impact of Climate on Hygiene Standards

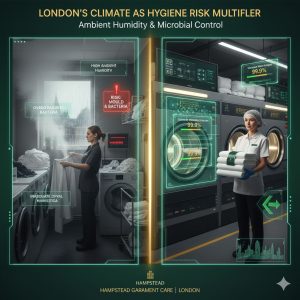

2. London’s Climate as a Hygiene Risk Multiplier

London’s climate plays a critical role in linen hygiene outcomes. Elevated ambient humidity, when combined with non‑industrial laundry systems, creates conditions that undermine effective microbial control.

London’s climate plays a critical role in linen hygiene outcomes. Elevated ambient humidity, when combined with non‑industrial laundry systems, creates conditions that undermine effective microbial control.

Key contributing factors include:

- Overloaded washing machines that reduce mechanical action

- Domestic or light‑duty dryers with limited thermal capacity

- Inadequate airflow during drying and storage

- Shortened drying cycles driven by time pressure

These conditions result in residual moisture retained within textile fibres. From a microbiological perspective, this moisture allows bacteria, mould, and odour‑producing organisms to survive post‑wash. As a result, linen may meet visual standards while failing to meet hygienic standards—a central and often overlooked component of linen hygiene risk in London.

3. Structural Limitations of In‑House Laundry Systems

Most in‑house laundry failures are not caused by poor intent or lack of effort. They arise from systems that are structurally misaligned with commercial hygiene requirements.

Most in‑house laundry failures are not caused by poor intent or lack of effort. They arise from systems that are structurally misaligned with commercial hygiene requirements.

Common points of failure include:

- Inconsistent wash temperatures that fail to achieve disinfection thresholds

- Insufficient mechanical agitation to remove embedded soils and microbes

- Incorrect detergent formulation or dosing

- Cross‑contamination between clean and soiled loads

- Incomplete moisture extraction before storage

From a risk management perspective, these failures compound. The outcome is a process with no validated hygiene result and no defensible documentation if guests, platforms, or regulators question standards.

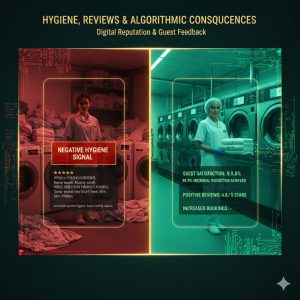

4. Hygiene, Reviews, and Algorithmic Consequences

Digital booking platforms increasingly treat hygiene‑related feedback as high‑priority behavioural data. In practice, this means that comments about towels, sheets, or overall cleanliness are not evaluated in isolation; they are aggregated and analysed at scale to assess property reliability and guest risk.

Digital booking platforms increasingly treat hygiene‑related feedback as high‑priority behavioural data. In practice, this means that comments about towels, sheets, or overall cleanliness are not evaluated in isolation; they are aggregated and analysed at scale to assess property reliability and guest risk.

Repeated review language such as:

- “Damp towels”

- “Musty smell”

- “Didn’t feel fresh.”

- “Skin irritation”

Platform algorithms interpret it as an indicator of systemic hygiene weakness rather than a one‑off incident. When similar terms appear across multiple stays, even at low frequency, they contribute to a negative hygiene signal within the platform’s internal scoring models.

These signals can activate automated responses, including:

- Reduced search ranking visibility

- Refund or compensation triggers

- Host or property warnings

- Long‑term listing suppression

Importantly, these mechanisms operate without human review. They are algorithmic rather than discretionary, meaning explanations, apologies, or corrective actions after the fact rarely reverse the impact. From a commercial perspective, this converts laundry hygiene failures directly into discoverability loss, revenue decline, and long‑term erosion of platform trust.

5. Regulatory Exposure and the Absence of a Single Standard

While the UK has no single statute governing linen hygiene, hospitality operators remain subject to multiple overlapping regulatory, professional, and legal expectations. These frameworks collectively define what is considered reasonable, defensible, and compliant practice within hotels, Airbnbs, spas, and serviced accommodation.

Key sources of obligation include:

- Environmental Health requirements, which assess hygiene risk based on outcomes and controls rather than intent

- Consumer duty‑of‑care principles, which require businesses to protect guests from foreseeable harm, including hygiene‑related skin reactions or infections

- Spa and wellness sanitation expectations, where towel and linen hygiene are directly linked to client safety

- Infection prevention and control guidance is increasingly referenced in post‑pandemic inspections and complaints.

Crucially, these frameworks do not require proof of negligence to create exposure. In regulatory or legal contexts, businesses are expected to demonstrate process control—clear evidence that hygiene risks are systematically managed and reduced.

Domestic or informal in‑house laundry operations provide no audit trail, no thermal or chemical validation, and no repeatable hygiene protocol. Without documented temperatures, dosing consistency, segregation controls, or moisture verification, operators cannot demonstrate that linen hygiene risks were reasonably managed.

As a result, when scrutiny arises—whether through an Environmental Health visit, a guest complaint, an insurance inquiry, or a platform investigation—businesses relying on domestic laundry are often left with explanations rather than evidence. This gap between intention and demonstrable control represents one of the most significant and underestimated components of linen hygiene risk in London.

6. Labour as a Hidden Cost Centre

Laundry operations consume significantly more labour than many hospitality operators anticipate, essentially because laundry is a fragmented, interruption‑prone process rather than a single task. Unlike front‑of‑house roles, laundry labour often expands invisibly across shifts, departments, and staff roles without being formally costed.

Laundry operations consume significantly more labour than many hospitality operators anticipate, essentially because laundry is a fragmented, interruption‑prone process rather than a single task. Unlike front‑of‑house roles, laundry labour often expands invisibly across shifts, departments, and staff roles without being formally costed.

A single laundry cycle may include:

- Sorting and segregation by fabric type, colour, and contamination risk

- Initial washing with manual programme selection

- Rewashing due to odour retention, residue, or visible marks

- Drying and redrying caused by moisture retention or machine limitations

- Folding, counting, and internal distribution

- Temporary or long‑term storage management

Each step introduces delay, supervision requirements, and re‑handling of the same items. In practice, linen may be handled by multiple staff members across shifts, increasing labour hours and raising the risk of cross‑contamination.

Cumulatively, this process can consume several hours of staff time per cycle, often during peak operational periods such as check‑out windows or spa turnover hours. From an operational-efficiency standpoint, this labour is diverted from guest‑facing and revenue‑generating activities, including housekeeping speed, room readiness, and service quality.

In London’s high‑cost labour environment—where wages, training, turnover, and scheduling inefficiencies compound—this diversion represents a substantial hidden expense. When evaluated at scale over weeks and months, labour absorbed by in‑house laundry frequently exceeds the cost of outsourcing to a professional commercial laundry provider, while delivering less predictable hygiene outcomes.

7. Textile Degradation and Accelerated Replacement

In‑house laundering accelerates textile degradation through mechanical, chemical, and thermal stressors that are difficult to control outside professional systems. While individual wash cycles may appear harmless, repeated exposure compounds damage at the fibre level, progressively reducing both performance and lifespan.

In‑house laundering accelerates textile degradation through mechanical, chemical, and thermal stressors that are difficult to control outside professional systems. While individual wash cycles may appear harmless, repeated exposure compounds damage at the fibre level, progressively reducing both performance and lifespan.

Key degradation mechanisms include:

- Fibre fatigue caused by excessive mechanical stress, particularly in overloaded machines, where friction and torsion increase micro‑fracturing of yarns

- Colour loss and greying are driven by improper wash chemistry, unstable pH levels, and detergent residues that strip dyes or redeposit soils.

- Reduced absorbency resulting from detergent, softener, and mineral buildup that coats fibres and inhibits moisture uptake—especially critical for towels and spa linens

- Premature thinning, tearing, and seam failure linked to uncontrolled heat, aggressive spin cycles, and inconsistent drying

From a textile science perspective, these forms of damage are irreversible. Once the fibre structure is compromised, no amount of reprocessing can restore the original softness, strength, or absorbency. The linen may still appear usable, but its functional performance continues to decline with each wash.

The economic consequence is accelerated replacement cycles for towels, sheets, and robes. Hospitality operators often underestimate this cost because degradation occurs gradually rather than as a single failure event. Linen is replaced earlier than planned, inventory levels expand to offset losses, and capital expenditure quietly increases.

Over time, these shortened replacement cycles become a persistent drain on operating budgets and a structural contributor to linen hygiene risk in London, as degraded textiles are more difficult to clean effectively, retain odours more easily, and fail to deliver consistent guest comfort.

8. Professional Laundry as a Risk Control System

Contemporary professional laundry services function as integrated risk management systems rather than simple service providers. Their primary role is not merely to clean linen, but to remove uncertainty from one of the most hygiene‑sensitive processes within hospitality operations.

Contemporary professional laundry services function as integrated risk management systems rather than simple service providers. Their primary role is not merely to clean linen, but to remove uncertainty from one of the most hygiene‑sensitive processes within hospitality operations.

Unlike in‑house or domestic laundry, professional systems are engineered around process validation—the ability to prove that hygiene outcomes are consistently achieved, not just assumed. This distinction is critical in environments where guest safety, regulatory scrutiny, and brand reputation intersect.

Key control mechanisms include:

- Validated wash temperatures aligned with recognised disinfection thresholds, ensuring microbial reduction is achieved rather than estimated

- Precisely controlled chemical dosing, calibrated to fabric type and soil load, preventing both under‑disinfection and chemical residue.

- Complete moisture extraction and industrial drying, eliminating the residual dampness that enables bacterial regrowth and odour formation.n

- Segregated workflows for soiled and clean linen, reducing the risk of cross‑contamination throughout the handling process

- Standardised operating protocols that deliver consistent, repeatable hygiene outcomes regardless of volume or seasonality

From a management and governance perspective, predictability is the primary benefit. Predictable outcomes allow operators to forecast costs, control quality, and respond confidently to external scrutiny. Instead of relying on staff judgment or best effort, hygiene performance becomes a controlled variable within the business.

In practical terms, professional laundry converts linen hygiene from a reactive problem—addressed only when complaints arise—into a proactive control system. This shift is central to reducing linen hygiene risk in London, as it replaces uncertainty with evidence, variability with consistency, and assumption with verification. Predictable, validated outcomes therefore form the foundation of effective operational risk control in modern hospitality.

9. Financial Impact Over a 12‑Month Horizon

When hospitality businesses evaluate laundry costs over a full operating year, accounting for:

- Energy inefficiency

- Labour diversion

- Accelerated linen replacement

- Rewash frequency

- Lost bookings linked to hygiene complaints

Professional laundry solutions consistently deliver a lower total cost of ownership and significantly reduce operational and reputational risk.

10. How Hampstead Garment Care Mitigates Linen Hygiene Risk

Hampstead Garment Care partners with London hotels, Airbnbs, and spas that recognise a fundamental operational reality: linen hygiene cannot be managed through effort alone. It requires structured systems, technical control, and repeatable outcomes.

At the core of our approach is a strategic but straightforward principle:

Linen hygiene is a form of brand risk management.

In practical terms, this means treating laundry not as a back‑office task, but as a controlled process that directly protects guest trust, reviews performance, and regulatory confidence.

Our commercial laundry systems are designed to address the specific failure points that create linen hygiene risk in London hospitality environments. We provide:

- Verified disinfection processes, using validated temperatures and chemistry to achieve consistent microbial reduction rather than assumed cleanliness

- Complete moisture control, ensuring linen leaves the process fully dry at fibre level, not just surface‑dry, reducing odour recurrence and microbial regrowth

- Long‑term fabric preservation, through controlled mechanical action and fabric‑appropriate chemistry that extends linen lifespan and maintains absorbency

- Predictable, transparent monthly pricing, allowing operators to forecast costs accurately without hidden labour, energy, or replacement surprises

Beyond the technical process, Hampstead Garment Care offers operational reliability. Linen is processed to consistent standards regardless of volume fluctuations, seasonal pressure, or staffing challenges. This stability allows hospitality operators to plan room turnovers, spa schedules, and housekeeping workflows with confidence.

The result is not convenience, but control. By removing variability, uncertainty, and undocumented risk from laundry operations, Hampstead Garment Care transforms linen hygiene from a recurring operational concern into a managed, auditable component of the business—reducing linen hygiene risk in London at its source.

Conclusion: Hygiene as a Strategic Operational Decision

In 2026, linen hygiene is no longer a housekeeping detail or an operational afterthought. Within London’s hospitality sector, it has become a strategic variable that directly shapes how a business is perceived, evaluated, and trusted by guests, platforms, and regulators alike.

In 2026, linen hygiene is no longer a housekeeping detail or an operational afterthought. Within London’s hospitality sector, it has become a strategic variable that directly shapes how a business is perceived, evaluated, and trusted by guests, platforms, and regulators alike.

It now functions simultaneously as:

- A trust determinant, influencing how safe, comfortable, and professionally managed a property feels from the guest’s first interaction

- A review and ranking factor, actively monitored and interpreted by booking platform algorithms that determine visibility and demand.

- A compliance consideration, where the absence of documented process control creates exposure during inspections, complaints, or disputes

- A profitability variable, affecting labour efficiency, linen lifespan, booking performance, and long‑term operating costs

From an operational perspective, linen sits at the convergence point of multiple risk domains. A single hygiene failure can cascade across departments—triggering guest dissatisfaction, staff disruption, negative digital signals, and regulatory attention. Conversely, consistent hygiene control stabilises operations, supports predictable service delivery, and removes uncertainty from day‑to‑day decision‑making.

Hospitality businesses that continue to treat laundry as a routine chore rely heavily on assumptions, individual effort, and informal judgment. Those that elevate laundry to a scientific, documented, and professionally managed process replace assumption with evidence and variability with control.

In a competitive and highly scrutinised market like London, this distinction is decisive. Operators who approach linen hygiene as a strategic operational discipline protect not only their textiles, but their reputation, resilience, and long‑term commercial viability—well before those assets are tested.

Keyword Context (Academic Use):

- Hospitality Hygiene London refers to the city‑specific application of hygiene control systems across hotels, Airbnbs, spas, and serviced accommodation, shaped by local climate, labour costs, and regulatory expectations.

- Hotel Linen Compliance UK outlines the obligation of hospitality operators to comply with overlapping UK standards for environmental health, consumer duty of care, and infection prevention, demonstrated through controlled laundry processes rather than visual cleanliness.

- Commercial Laundry London denotes industrial‑scale laundry operations that deliver validated disinfection, moisture control, and textile preservation at volumes and consistency levels not attainable with domestic or in‑house systems.

No comment