Luxury Clothing Care London – Premium Garment Cleaning & Preservation by Hampstead Garment Care

Introduction – Why Luxury Clothing Requires Specialist Care in London

London’s fashion ecosystem is defined by craftsmanship: Savile Row tailoring, luxury ready-to-wear, and designer wardrobes curated across Hampstead, North London, and Central London. In this context, luxury garments are more than clothing—they are capital-intensive assets with complex materials, specialist construction, and high expectations for presentation.

However, the primary risk to luxury garments is not necessarily wear. In many cases, the most significant cumulative damage occurs during cleaning. Standard, volume-driven dry cleaning models often rely on uniform processing cycles, limited diagnostic assessment, and rapid finishing. That operational logic is compatible with basic garments—but it can be incompatible with high-value items.

This is the purpose of Luxury Clothing Care London: a specialist approach that prioritises fabric science, controlled processing, and technical finishing. At Hampstead Garment Care, we provide premium garment cleaning, restoration, and preservation for clients who require repeatable, high-precision results. Our work extends beyond conventional dry cleaning by applying individual assessment, fibre-appropriate methods, and rigorous quality control.

If you own high-value garments (designer, bespoke, or sentimental), this guide outlines why specialist luxury care matters and why Hampstead Garment Care is trusted across London.

What Is Luxury Clothing Care?

Luxury clothing care is a high-specification cleaning and preservation service designed for garments that require advanced, fabric-specific handling. The objective is not merely surface cleanliness; it is the long-term preservation of fibre integrity, colour saturation, and garment architecture.

Luxury clothing care is a high-specification cleaning and preservation service designed for garments that require advanced, fabric-specific handling. The objective is not merely surface cleanliness; it is the long-term preservation of fibre integrity, colour saturation, and garment architecture.

Unlike mass-market dry cleaning, Luxury Clothing Care London is built on garment-level decision-making. Each item is evaluated as a unique object with specific risks and constraints.

Luxury Clothing Care London typically includes:

- Individual garment inspection (not batch processing): Each garment is assessed independently for fibre type, construction (e.g., canvassing, interlinings), trims, prior wear, and known weak points. This reduces the risk of applying the wrong process to a high-value item.

- Fibre-appropriate cleaning chemistry and detergents: Cleaning agents are selected based

- on fibre behaviour (protein fibres such as wool/cashmere vs cellulose fibres such as cotton/linen vs synthetics). This is critical because incorrect chemistry can strip dyes, weaken fibres, or alter handle (texture).

- Low-impact cleaning systems for delicate textiles: We use processes that minimise mechanical stress (agitation and friction) because many luxury fabrics fail through micro-abrasion. Reduced mechanical action protects sheen, surface finish, and fibre alignment.

- Controlled moisture and temperature management: Moisture levels and heat exposure are controlled throughout cleaning and drying to prevent shrinkage, seam distortion, dye migration, and texture flattening—especially in silk, structured tailoring, and knitwear.

- Hand finishing, reshaping, and precision pressing: Finishing is a technical stage in which structure is restored (shoulders, lapels, drape) using trained pressing techniques, proper steam control, and shaping tools—rather than fast, high-pressure pressing.

- Colour retention strategies (including separation protocols): Garments are separated by colour family and dye sensitivity. This reduces colour transfer, prevents dulling, and preserves the saturation and tonal depth expected in designer items.

- Protection of trims, linings, and embellishments: Buttons, zips, beadwork, sequins, leather details, and speciality linings often have a different tolerance than the main fabric. They are protected through selective covering, reduced exposure, or alternative processing.

- Long-term garment longevity planning: Beyond one clean, luxury care aims to slow cumulative degradation by recommending appropriate cleaning frequency, stain intervention timing, and storage/preservation methods to extend wearable life.

The fundamental goal is preservation.

At Hampstead Garment Care, we develop a tailored care plan for each piece based on:

- Fibre type and textile structure

- Garment construction and interlinings

- Colour stability and dye sensitivity

- Stain category and soiling profile

- Existing wear patterns and weak points

- Whether the garment requires restoration or routine maintenance

This technical, preventive model is the core of Luxury Clothing Care London.

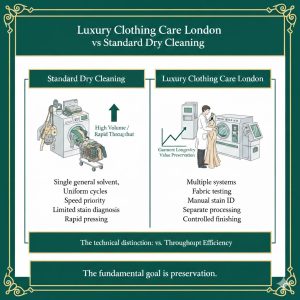

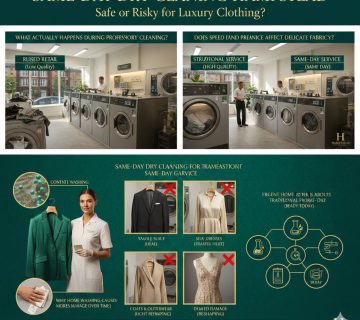

Luxury Clothing Care London vs Standard Dry Cleaning (A Technical Distinction)

It is inaccurate to treat all dry cleaning providers as equivalent. The difference is not cosmetic—it is structural and technical, rooted in how garments are evaluated, how risks are controlled, and how finishing is executed.

It is inaccurate to treat all dry cleaning providers as equivalent. The difference is not cosmetic—it is structural and technical, rooted in how garments are evaluated, how risks are controlled, and how finishing is executed.

A standard dry cleaner is typically engineered for throughput: high volume, rapid turnaround, and minimal manual intervention. A luxury garment care provider is engineered for risk management and craftsmanship: diagnostic assessment, controlled processing conditions, and repeatable finishing standards.

To understand the distinction, it helps to treat garment cleaning like clinical treatment: basic services follow a standard protocol; specialist services first diagnose, then select the safest intervention.

Standard dry cleaning is commonly:

- Utilises a single general solvent system: Many operators rely on one main solvent approach applied broadly, regardless of garment complexity.

- Applies uniform cycles to varied garment types: Tailored jackets, knitwear, and embellished dresses may be cleaned under similar cycle conditions, despite having different failure risks.

- Prioritises speed and processing efficiency: Faster throughput often means reduced inspection time, simplified stain handling, and fewer customised cycles.

- Performs limited manual stain diagnostics: Stains may be treated generically without determining whether they are lipid-, protein-, or tannin-based, or due to dye transfer, etc.

- Relies on rapid pressing (sometimes with excessive heat/pressure): This can create glazing (shine) in wool, flattening in silk/satin, or imprints in structured garments.

Luxury clothing care focuses on:

- Multiple systems (solvent cleaning, wet cleaning, selective hand cleaning): The method is chosen based on fibre behaviour and construction, not tradition.

- Fabric testing before processing: Colourfastness and fibre-sensitivity tests reduce the risk of dye migration, texture changes, or shrinkage.

- Manual stain identification and controlled pre-treatment: Stain chemistry is analysed (e.g., oils vs sugars vs tannins) so removal is targeted and safer.

- Separate processing for delicate, structured, or dyed garments: High-risk items are isolated to prevent cross-contamination and reduce mechanical stress.

- Controlled finishing with reshaping and structural correction: Finishing restores drape and silhouette through skilled technique, not speed.

Why this matters long-term (the garment ageing model)

Luxury garments degrade most commonly through cumulative micro-damage rather than a single catastrophic failure. This means the garment rarely fails in one obvious event (like a tear). Instead, it weakens gradually over repeated cleaning cycles, which cause small, often invisible forms of stress. Over time, these small stresses compound, and the garment begins to show visible ageing: dull colour, loss of drape, stiffness, and shape instability.

To explain it clearly: luxury garments are engineered systems. They are made from fibres, yarns, weaves/knits, dyes, linings, canvassing, and seams, all of which react differently to chemistry, heat, moisture, pressure, and mechanical action. When cleaning variables are poorly controlled, each cycle creates minor degradation. After enough cycles, the degradation becomes noticeable—and in many cases irreversible.

Standard processing increases the risk of:

- Repeated fibre abrasion: Even “gentle” cycles create friction. With luxury materials, abrasion can break fibre tips, disturb surface alignment, and reduce the refined finish (especially in cashmere, fine wool, brushed fabrics, and delicate weaves). This is one of the main reasons a garment looks older than its actual age.

- Gradual colour dulling: Colour loss is not always dramatic fading. Often it appears as reduced depth (black becomes grey, navy becomes flat) caused by dye stress, micro-surface damage that changes light reflection, and residue build-up that disrupts colour clarity.

- Reduction in fabric hand (the feel/softness): “Hand” refers to the tactile behaviour of the textile: softness, bounce, smoothness, and flexibility. Incorrect chemistry, over-drying, excessive heat, or aggressive finishing can remove natural oils, flatten fibres, and create stiffness.

- Structural fatigue in interlinings and canvassing: Tailored garments rely on internal architecture (interlinings, canvassing, padding). Excess moisture, high temperatures, or harsh mechanical action can weaken adhesion, distort internal layers, and reduce structural stability—leading to shoulder collapse, bubbling, or lapel roll distortion.

- Seam torque and distortion (especially in blends): Fabric blends shrink or relax at different rates. If moisture and drying are not controlled, seams can twist, panels can pull, and the garment loses balance. This is why sleeves may rotate, trouser legs may twist, or hems may become uneven over time.

Luxury garment care reduces those risks by controlling the variables that create micro-damage:

- lower mechanical stress (reduced friction and agitation)

- controlled heat exposure

- controlled moisture levels and drying speed

- fibre-appropriate chemistry and pH

- garment separation by colour and sensitivity

- specialist finishing with reshaping rather than forceful pressing

Luxury clothing care is slower because it is analytical and preventive: it uses diagnostic assessment, variable control, and skilled finishing to protect garment performance over the years, rather than just achieving a visually clean result today. Importantly, luxury garments are designed and manufactured with slow, deliberate methods—layering, stitching, canvassing, and engineered structure—so maintenance should match the same level of care.

Which Garments Require Luxury Clothing Care?

Not every garment requires specialist processing. However, certain categories carry a substantially higher risk profile and should routinely be treated under Luxury Clothing Care London protocols.

Not every garment requires specialist processing. However, certain categories carry a substantially higher risk profile and should routinely be treated under Luxury Clothing Care London protocols.

To clarify what “higher risk profile” means in practical terms, these garments typically include one or more of the following risk factors:

- High-sensitivity fibres: Protein fibres (e.g., silk, cashmere, fine wool, alpaca) are more vulnerable to heat, friction, and chemical imbalance. Even minor mistakes can alter softness, sheen, or cause irreversible distortion.

- Complex garment architecture: Tailored and structured pieces contain internal components (canvassing, interlinings, padding, fusing) that behave differently from the outer fabric. If cleaning variables are not controlled, the structure can collapse, bubble, or deform.

- Dye instability and colour depth requirements: Designer garments often use saturated or speciality dyes. These dyes can be sensitive to pH, solvent exposure, and moisture—making them more prone to dulling, tone shift, or dye migration.

- Decorations and mixed materials: Beading, sequins, embroidery, speciality threads, leather trims, and glued elements introduce multiple material tolerances within a single item. A process safe for the fabric may damage the decoration, and vice versa.

- Low tolerance for finishing errors: Luxury garments rely on drape, silhouette, and surface finish. Excessive heat, pressure, or poor pressing technique can create glazing (shine), seam imprints, flattening, or texture loss.

Because these garments have a narrow safety margin, they should not be cleaned with a general “one-process” cleaning method. Instead, they benefit from specialist assessment, controlled processing conditions, and hand finishing—the technical foundation of Luxury Clothing Care London.

1) Designer Dresses & Evening Gowns

Silk, chiffon, satin, organza, and embellished garments require controlled moisture levels and low mechanical stress.

Luxury eveningwear is typically manufactured using fine filament yarns, delicate weaves, and specialist finishing that creates drape, sheen, and movement. Many of these textiles are sensitive to friction, heat, and uncontrolled moisture. In addition, designer gowns often include mixed materials (beads, sequins, bonded trims, glued elements, specialist threads), each with different chemical and thermal stability.

London-specific example: This is particularly important for black designer dresses worn to London events (Mayfair, Knightsbridge, theatre nights), where even minor colour dulling or dye shift is instantly noticeable under evening lighting.

From a technical standpoint, the key challenges are:

- Dye sensitivity: Many fashion dyes used in silk and satin are sensitive to pH and moisture changes, increasing the risk of colour shift.

- Surface damage risk: Satin, chiffon, and organza can snag or scuff easily due to their structure.

- Decoration vulnerability: Beading and sequins may loosen under mechanical action; adhesives can degrade under solvent or heat.

Common risks: dye migration, snagging, distortion, and loosening of embellishment.

2) Tailored Suits & Structured Jackets

Wool, cashmere, mohair, and high-twist suiting fabrics rely on a stable structure.

Tailored garments should be understood as engineered systems, not simple fabric shells. They contain internal architecture such as canvassing, padding, and interlinings, designed to create shape (shoulders), roll (lapels), and drape (front panels). If cleaning introduces excessive moisture, heat, or poor finishing pressure, internal layers can move, distort, or fatigue.

London-specific example: For Savile Row suits and City tailoring, improper cleaning often shows up as lapel distortion, shoulder collapse, or a glossy finish—exactly the kind of damage that makes a premium suit look cheap.

Key technical issues include:

- Glazing (shine) formation: Wool fibres can flatten under heat + pressure, altering surface reflectance.

- Structure fatigue: Interlinings can lose stability, creating bubbling or collapse.

- Panel imbalance: Poor moisture control can create differential shrinkage/relaxation.

Common risks: glazing/shiny patches, shoulder collapse, and lapel distortion.

3) Couture & Bespoke Pieces

Bespoke garments often include internal canvassing, layered interlinings, and hand-stitched assembly.

Couture and bespoke clothing are often built with non-standard internal construction, including floating canvases, hand pad-stitching, speciality linings, and unusual fibre blends. Unlike mass-market garments, the internal mechanics are not always designed to tolerate generic processing.

Because couture pieces often have:

- multiple internal layers with different shrink/relax behaviour

- hand stitching that responds differently to moisture

- delicate surface finishes

They require cleaning and finishing that is both conservative and highly controlled.

Common risks: interlining separation, rippling, and permanent shape disruption.

4) Cashmere, Alpaca & Fine Wool Knitwear

Knitwear fibres degrade rapidly under agitation and uncontrolled drying.

Fine knitwear is vulnerable because its stability depends on its loop structure rather than a rigid woven architecture. Mechanical agitation stretches loops, and uncontrolled drying causes uneven tension, which can permanently alter fit.

Additionally, cashmere and alpaca fibres are prone to:

- surface fibrillation: fibre ends lift and break, increasing pilling

- handle degradation: over-drying or incorrect chemistry reduces softness

- shape drift: drying position and tension can stretch hems and sleeves

Common risks: shrinkage, stretching, pilling, and fibre roughness.

5) Leather & Suede Garments

These require specialist treatment, reconditioning, and controlled drying.

Leather and suede are not traditional textiles; they are processed skins that require preservation with oils, dyes, and surface finishes. Cleaning removes contamination but can also remove essential oils, leaving the material dry, stiff, or uneven.

Technical considerations include:

- Moisture control: too much moisture can deform and harden leather

- Finish preservation: surface coatings can crack or cloud

- Reconditioning requirement: oils must be replenished to restore flexibility

Common risks: stiffness, drying cracks, colour shift.

6) Wedding Dresses & Formal Wear

Frequently multi-material with lace, boning, tulle, beads, and multiple linings.

Wedding dresses are among the most complex garments a cleaner can handle. They often combine:

- protein fibres (silk) and synthetics (tulle/polyester)

- lace and mesh structures

- boning and structured bodices

- heavy embellishment

This creates a significant risk because each component tolerates cleaning differently. Preservation also matters: many gowns are stored long-term, so incorrect residue or moisture control can trigger yellowing or fibre degradation over time.

Common risks: yellowing, lace damage, irreversible texture loss.

If your wardrobe contains any of these, specialist handling is not optional—it is protective.

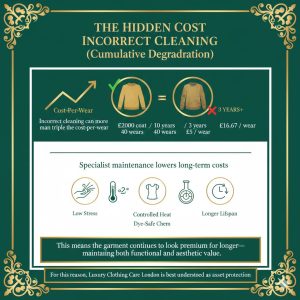

The Hidden Cost of Incorrect Cleaning (Cumulative Degradation)

Luxury garments are rarely ruined in a single event. Instead, they undergo cumulative degradation that gradually reduces performance and aesthetics:

Luxury garments are rarely ruined in a single event. Instead, they undergo cumulative degradation that gradually reduces performance and aesthetics:

- Fibre thinning and micro-breakage

- Loss of colour depth and saturation

- Texture flattening or drying

- Drape instability

- Shape distortion over time

Critically, once luxury fibres are structurally compromised, restoration options are limited.

For this reason, Luxury Clothing Care London is best understood as preventive maintenance—designed to reduce irreversible wear.

Hampstead Garment Care – Our Luxury Cleaning Process

High-end garment care requires a structured, repeatable system.

At Hampstead Garment Care, each garment follows a multi-stage workflow designed to minimise risk and maximise preservation.

1) Detailed Inspection

We evaluate:

- Fibre type, weave, and garment construction: We identify whether the item is woven, knitted, or engineered (bonded/laminated), and whether it is a protein fibre (silk/wool/cashmere), cellulose fibre (cotton/linen), or synthetic blend. This matters because each fibre group has a different tolerance for moisture, pH, heat, and mechanical action.

- Structural components (linings, canvassing, padding): In luxury garments—especially tailored suits and coats—the internal architecture can include canvassing, fusing, shoulder pads, chest pieces, or speciality interlinings. These elements can shrink, soften, delaminate, or distort if exposed to incorrect moisture or heat.

- Trims (buttons, zips, beadwork, threads): Trims often have lower tolerance than the outer fabric. Metal components may oxidise; beads and sequins may scratch or loosen; specialist threads may react to solvent or heat. We assess whether trims need protection, removal, or alternate cleaning.

- Wear issues and stress points: We look for weakened seams, abrasion zones (underarms, cuffs, hems), friction damage, and fabric fatigue. This step is essential because luxury garments can fail at stress points during cleaning if not handled conservatively.

- Stain presence and likely chemistry: We determine the probable stain class—lipid/oil, protein, tannin, pigment, oxidation, or dye transfer—because each requires a different removal strategy and poses different risks to dye stability.

This inspection stage functions like a diagnostic exam: it prevents incorrect processing choices and reduces the probability of irreversible damage.

2) Fabric & Colour Testing

We assess colourfastness and fibre sensitivity to determine safe processing parameters.

Practically, this step answers two questions:

- Will the dye remain stable under the proposed cleaning system? (risk of bleeding, tone shift, or dulling)

- Will the fibre maintain its structure and surface finish? (risk of shrinkage, sheen loss, flattening, or texture change)

For example, certain black designer garments can appear colourfast but still lose depth if the wrong chemistry or drying profile is used. Testing prevents that.

3) Specialist Pre-Treatment

Stains are treated using controlled chemistry and methods designed to avoid aggressive agitation.

Stains are treated using controlled chemistry and methods designed to avoid aggressive agitation.

Luxury stain removal is not about scrubbing harder—it is about using the correct chemistry with controlled dwell time. We select treatment methods based on:

- stain category (oil, tannin, protein, pigment)

- fibre type and dye sensitivity

- stain age (fresh vs oxidised/set)

We use a targeted application so that the stain is broken down without weakening fibres or stripping dye.

4) Controlled Cleaning System Selection

Based on garment type and risk profile, we select the safest method:

- Gentle solvent cleaning: Used when moisture must be minimised, or construction is sensitive. It reduces swelling and the risk of distortion in certain luxury textiles.

- Professional wet cleaning: Used when water-based soiling is present, and the fibre can tolerate controlled moisture. Unlike domestic washing, wet cleaning uses calibrated mechanical action, temperature control, and professional finishing.

- Selective hand-cleaning for high-risk zones: Certain garments require hand-cleaning in specific areas (collars, underarms, trims, embellishments) to reduce mechanical stress and protect delicate components.

This is the key technical difference between luxury care and conventional processing: the method is chosen for the garment, not for the workflow.

5) Post-Clean Inspection

We evaluate stain removal success and confirm fabric condition.

This is not a glance. We check:

- any remaining stains or shadowing

- colour consistency and tone depth

- texture integrity (e.g., silk sheen, wool surface)

- shape stability (no distortion)

If further controlled treatment is required, it is performed before finishing.

6) Hand Finishing & Restoration

Garments are reshaped, pressed, and structurally restored using skilled technician finishing.

Finishing is a technical restoration stage where we:

- Rebuild garment silhouette (lapels, shoulders, drape)

- control steam and pressure to avoid glazing/imprints

- restore natural fall and balance

- correct shape drift caused by wear

In luxury garment care, finishing quality often determines whether the garment looks truly “premium” after cleaning.

7) Final Quality Control

A final inspection occurs before presentation packaging.

We confirm:

- garment symmetry and shape

- stain-free result

- correct finish standard

- trim integrity

- client-ready presentation

This workflow delivers consistent, high-quality, technically reliable outcomes for Luxury Clothing Care London—because results are built from controlled steps, not speed.

Advanced Technology for Luxury Garment Cleaning

Technology improves safety and consistency—but it does not replace expertise.

Technology improves safety and consistency—but it does not replace expertise.

In luxury garment care, technology should be understood as a risk-control tool. It helps us control the variables that typically cause damage in standard processing: excessive mechanical action, uncontrolled heat, inconsistent moisture, and poor drying profiles. However, technology is only valuable when it is paired with technical judgement—because the correct settings depend on fibre behaviour, garment construction, dye stability, and stain chemistry.

To put it simply:

- Machines control conditions.

- Technicians control decisions.

Our systems support precision through the following specialist technologies:

- Low-impact hydrocarbon solvent cleaning: Hydrocarbon systems use a gentler, less aggressive solvent profile than older, harsher dry-cleaning methods. The advantage is improved protection of delicate trims, reduced fibre stress, and better preservation of the garment’s “hand” (feel). It is especially useful for structured tailoring, high-value outerwear, and garments that require tight moisture control.

- Professional wet-cleaning technology: Wet cleaning is not domestic washing. It is a calibrated professional system using controlled mechanical action, controlled chemistry, and specialist drying/finishing. This makes it particularly effective for water-based soils (sugars, salts, perspiration residues) while keeping shrinkage and distortion risks low—especially in fine wool, silk blends, and delicate designer pieces.

- Temperature-controlled cycles: Heat is one of the main causes of luxury garment degradation (shrinkage, texture flattening, dye stress). Temperature control allows us to clean and dry within safe ranges for protein fibres (silk/wool/cashmere) and prevents structural components (interlinings, fusing) from softening or deforming.

- Moisture-regulated drying: Luxury garments often fail during drying, not during washing. Moisture regulation prevents over-drying (which causes stiffness, fibre brittleness, and texture loss) and uneven drying tension (which causes seam torque, sleeve twisting, and shape imbalance). This is critical for cashmere knitwear, delicate wools, and structured pieces.

- Anti-pilling finishing systems for knitwear: Pilling is a surface-fibre failure where broken fibre ends tangle into pills. Anti-pilling finishing reduces loose fibre ends and helps stabilise the knit surface without harsh abrasion. This protects the premium appearance of cashmere, alpaca, and fine-wool knitwear through repeated care cycles.

Machines provide control. Technicians provide judgment—because a luxury result comes from selecting the correct method, not simply using modern equipment.

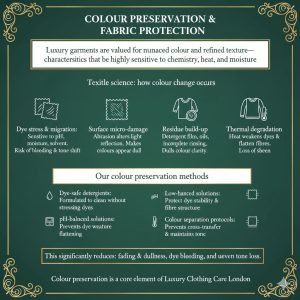

Colour Preservation & Fabric Protection

Luxury garments are valued for nuanced colour and refined texture—characteristics that are highly sensitive to chemistry, heat, and moisture.

Luxury garments are valued for nuanced colour and refined texture—characteristics that are highly sensitive to chemistry, heat, and moisture.

To understand why colour protection matters, it helps to recognise that “colour” in luxury clothing is not only a pigment. It is part of the garment’s entire visual identity: depth, richness, and surface reflectance. In designer garments, especially black, navy, deep red, and jewel tones, even slight chemical imbalance or heat stress can make the item look older, flatter, or cheaper.

From a textile science perspective, colour change occurs through several mechanisms:

- Dye stress and migration: Some dyes are inherently sensitive to pH, moisture, and solvent interaction. If conditions are not controlled, dyes can migrate within the fibre or transfer to other fabrics.

- Surface micro-damage: Micro-abrasion changes how light reflects off the fabric surface. This makes colours appear dull even if the dye itself hasn’t “faded” dramatically.

- Residue build-up: Detergent residues, body oils, and incomplete rinsing can create a film that dulls colour clarity—particularly noticeable on dark luxury garments.

- Thermal degradation: Heat can weaken dyes and flatten the fibre structure, leading to a loss of sheen (silk/satin) or crispness (tailoring and wool).

For this reason, colour preservation is not a cosmetic extra—it is a core element of Luxury Clothing Care London.

We therefore use:

- Dye-safe detergents: Formulated to clean without stripping or stressing dyes, particularly in saturated designer colours.

- pH-balanced solutions: pH control protects dye stability and prevents fibre swelling or brittleness, especially in protein fibres like silk and wool.

- Low-heat, controlled processes: Reduced thermal exposure prevents dye weakening, texture flattening, and sheen loss.

- Colour separation protocols: Garments are separated by dye sensitivity and colour family to prevent cross-transfer and maintain tone consistency.

This significantly reduces:

- fading and dullness (loss of depth, not just obvious fading)

- dye bleeding (colour transfer and migration)

- uneven tone loss (patchiness, shadowing, and tone shift)

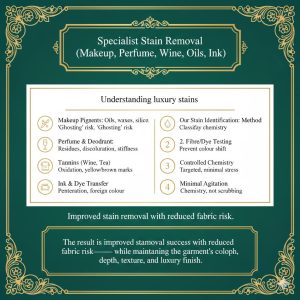

Specialist Stain Removal (Makeup, Perfume, Wine, Oils, Ink)

Luxury garments often encounter complex stains that require targeted approaches, as stains are not simply “dirt.” From a textile-care perspective, stains are chemical events that bond to fibres in different ways. The removal strategy must therefore match both the stain chemistry and the fibre/dye sensitivity of the garment.

Luxury garments often encounter complex stains that require targeted approaches, as stains are not simply “dirt.” From a textile-care perspective, stains are chemical events that bond to fibres in different ways. The removal strategy must therefore match both the stain chemistry and the fibre/dye sensitivity of the garment.

A key principle in Luxury Clothing Care London is that stain removal is a controlled scientific process, not aggressive scrubbing. Scrubbing increases mechanical damage, forces contaminants deeper into the fibre structure, and often causes surface abrasion—especially on silk, satin, cashmere, and fine wool.

Understanding luxury stains (what they are technically)

Luxury garments typically encounter stains that fall into distinct chemical categories:

- Cosmetic pigments (makeup/foundation): Often a mixture of oils, waxes, silicones, and fine pigments designed to be long-wearing. These bind strongly to fibres and can leave “ghosting” if treated generically. Removal requires controlled solvent action and careful pigment lifting to avoid dye disruption.

- Perfume and deodorant residues: These are not simple marks; they frequently contain alcohols, fragrance oils, aluminium salts, and polymer residues. Over time, they can cause discolouration, stiffness, and even fibre degradation in underarm zones. Treatment requires breaking down the residue while preserving dye stability.

- Lipid-based body oils (collars/cuffs): Oils oxidise over time, turning into sticky, darker residues that attract particulate soil. On luxury garments, this can create visible ring marks and long-term dulling. Effective removal often involves staged degreasing rather than one-step cleaning.

- Tannins (red wine/tea/coffee): Tannin molecules bind to fibres and can oxidise, leading to persistent yellow/brown staining. On silk and light wool, incorrect treatment can set the stain permanently or cause bleaching/halo effects.

- Food oils: These are high-risk because they often become invisible after initial cleaning, then reappear during pressing (heat makes residue visible). Correct luxury treatment requires oil detection, degreasing, and controlled finishing.

- Ink and dye transfer: Ink includes dyes and solvents that can penetrate quickly. Dye transfer is particularly difficult because it is not “dirt”—it is a foreign colour that has migrated into the fibre. Removal requires careful testing and controlled chemistry to avoid stripping the garment’s original dye.

Why non-specific stain removal is risky

Each stain category interacts differently with fibres and dyes. A non-specific approach can cause:

- fibre weakening (from harsh chemistry or aggressive rubbing)

- colour stripping (dye loss, tone shift)

- halo marks (uneven removal, leaving rings)

- texture disruption (loss of silk sheen, wool surface damage)

Our stain-removal method (Luxury Clothing Care London protocol)

Our method emphasises controlled, evidence-based steps:

- Stain identification: We classify the stain (oil, tannin, pigment, protein, dye transfer) to select the correct approach.

- Fibre/dye testing: We test dye sensitivity and fibre stability to prevent colour shift or surface damage.

- Controlled chemistry: We use targeted chemistry with controlled dwell time and rinsing to break bonds safely.

- Minimal mechanical stress: We avoid aggressive agitation and rely instead on chemistry and controlled handling.

The result is improved stain removal success with reduced fabric risk—while maintaining the garment’s colour depth, texture, and luxury finish.

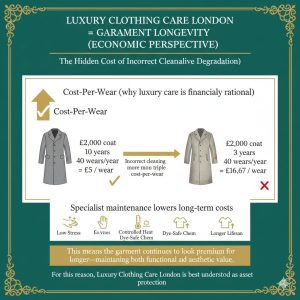

Luxury Clothing Care London = Garment Longevity (Economic Perspective)

Luxury garments represent a significant financial investment, and their value should be evaluated not only by purchase price but by total lifetime cost and cost-per-wear.

Luxury garments represent a significant financial investment, and their value should be evaluated not only by purchase price but by total lifetime cost and cost-per-wear.

When a garment such as a £2,000 coat is cleaned incorrectly, the damage is often cumulative and subtle rather than immediate. The garment may still look “acceptable” after one poor cleaning, but repeated inappropriate processing can accelerate ageing mechanisms such as fibre abrasion, loss of surface finish, dye dulling, and structural fatigue in tailoring components. This shifts the garment’s usable life from a long-term asset (often 8–12 years for a high-quality coat) into a short-term item that looks prematurely worn after only a few seasons.

Cost-per-wear (why luxury care is financially rational)

A simple economic model illustrates this clearly:

- If a £2,000 coat lasts 10 years, worn 40 times per year → 400 wears

Cost-per-wear = £5 - If the same coat is damaged by inappropriate cleaning and lasts only 3 years, worn 40 times per year → 120 wears

Cost-per-wear = £16.67

In other words, incorrect cleaning can more than triple the cost-per-wear, even before considering secondary costs such as:

- replacement tailoring/repairs

- emergency stain treatment failures

- reduced resale value (for designer items)

- loss of aesthetic performance (colour depth, drape, silhouette)

Why specialist maintenance lowers long-term costs

Specialist maintenance reduces replacement costs by extending wearable life through:

- controlled mechanical stress (less fibre wear)

- controlled heat and moisture (less shrinkage and distortion)

- dye-safe chemistry (better colour retention)

- improved finishing quality (better silhouette and structure)

This means the garment continues to look premium for longer—maintaining both functional and aesthetic value.

For this reason, Luxury Clothing Care London is best understood as asset protection: it preserves the financial and aesthetic returns on garments designed to last, not to be replaced.

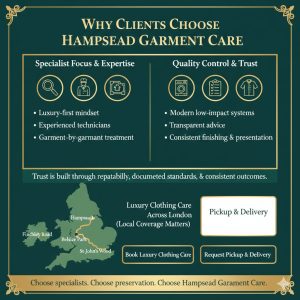

Why Clients Choose Hampstead Garment Care

Luxury clients prioritise outcome quality and reliability because high-value garments carry both financial value and reputational value: they affect how a person presents themselves, and they are difficult (or impossible) to replace in the same quality once damaged.

Luxury clients prioritise outcome quality and reliability because high-value garments carry both financial value and reputational value: they affect how a person presents themselves, and they are difficult (or impossible) to replace in the same quality once damaged.

For this reason, clients do not choose a luxury cleaner the same way they choose a convenience service. They choose based on risk reduction, consistency, and technical competence.

Key reasons clients choose Hampstead Garment Care include:

- Specialist focus on luxury garments (not general processing): We operate with a luxury-first mindset. That means our workflow is designed around high-risk items (silk, cashmere, tailoring, couture), rather than being optimised for low-cost bulk volume. Luxury garments receive dedicated attention, conservative handling, and appropriate method selection.

- Experienced technicians: Skill matters in luxury care because a machine does not produce many quality outcomes—they come from judgement. Experienced technicians can quickly identify fibre behaviour, stain type, and construction risks, and know how to prevent common failures such as glazing in wool, dye dulling in black garments, and distortion in structured pieces.

- Garment-by-garment treatment: Each garment is treated as an individual unit, not as part of a mixed batch. This reduces cross-contamination risk, prevents dye transfer, and allows the cleaning method to be aligned precisely with the garment’s fibre, structure, and sensitivity.

- Modern low-impact systems: Our equipment supports luxury outcomes through precise control of mechanical action, temperature, and moisture. This reduces fibre abrasion, protects texture, and improves repeatability. However, the technology is used as a tool—not as a substitute for expertise.

- Transparent advice and realistic expectations: Luxury garment care is fundamentally about controlled outcomes. We provide honest assessments, explain risks where applicable, and advise on the safest approach. This is important because some stains (especially oxidised dyes or long-set residues) have limited safe removal options.

- Consistent finishing and presentation: Luxury garments are defined by their silhouettes, drapery, and surface finishes. Proper finishing requires trained technique, correct steam/pressure control, and reshaping. Consistency matters: clients want the same premium outcome each time, not variable results.

Ultimately, trust in luxury garment care is built the same way as trust in any technical service: through repeatability, documented standards, and outcomes that remain consistent over time.

Luxury Clothing Care Across London (Not Only Hampstead)

We are based on Finchley Road, Hampstead (NW3) and serve clients across:

- Hampstead

- Finchley Road

- West Hampstead

- Swiss Cottage

- Belsize Park

- St John’s Wood

- Golders Green

- Highgate

- Camden

- Central London

From a local service perspective, this location is strategically positioned to support clients in both North and Central London. Finchley Road serves as a major transport corridor, providing efficient access to surrounding neighbourhoods with high concentrations of luxury households and professional clients.

Why local coverage matters in Luxury Clothing Care London

Local coverage is not only about convenience—it is a quality-control advantage. Luxury garments benefit from professional handling when:

- transport time is minimised (reducing crushing, creasing, and humidity exposure)

- Garments are moved in appropriate packaging

- collection and return can be coordinated quickly after events (weddings, formal dinners, travel)

Drop-off, collection, and pickup & delivery (how it supports garment preservation)

We also offer practical drop-off, collection options, and pickup & delivery where available. These services are designed to maintain quality and reduce risk by:

- limiting unnecessary folding and friction damage

- ensuring structured garments (coats, suits) remain supported during transport

- reducing the likelihood of clients attempting home stain treatment or incorrect interim cleaning

For luxury clients, logistics is part of garment care—because how a garment is handled outside the cleaning process still affects the outcome.

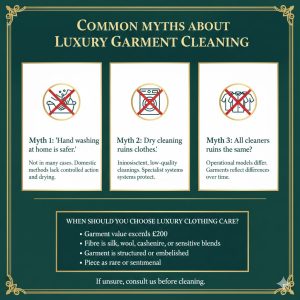

Common Myths About Luxury Garment Cleaning

Myth 1: “Hand washing at home is safer.”

Myth 1: “Hand washing at home is safer.”

In many cases, it is not. Domestic washing rarely provides controlled mechanical action, moisture management, and safe drying for luxury fibres.

Myth 2: “Dry cleaning ruins clothes.”

Inconsistent or low-quality dry cleaning can cause damage. Specialist cleaning systems are designed to protect garments.

Myth 3: “All cleaners are the same.”

Operational models differ substantially. Garments reflect these differences over time.

When Should You Choose Luxury Clothing Care?

Choose Luxury Clothing Care London when:

- The garment value exceeds £200

- The fibre is silk, wool, cashmere, alpaca, mohair, or sensitive blends

- . The garment is structured, tailored, or engineered

- . The garment contains embellishments or specialist trims

- . The piece is rare, sentimental, or difficult to replace

If unsure, consult us before cleaning.

Book Luxury Clothing Care London

Luxury garments require expert handling and controlled methods.

✅ Same-week service available (subject to garment type and workload).

🌍 Book online:

💬 WhatsApp booking:

📍 Hampstead Garment Care

513 Finchley Road, Hampstead, London NW3 7BB

📞 +44 02077949096

🚚 Pickup & Delivery options across London

Choose specialists. Choose preservation. Choose Hampstead Garment Care.

Frequently Asked Questions (FAQ Schema)

What is luxury clothing care?

Luxury clothing care is a specialist cleaning and preservation service for high-end garments using fabric-specific methods, gentle handling, and controlled finishing.

Is luxury clothing care better than normal dry cleaning?

Yes. Luxury clothing care focuses on individual assessment, fabric testing, controlled cleaning systems, and technical finishing rather than mass processing.

Which fabrics need specialist garment care?

Silk, cashmere, wool, alpaca, velvet, linen blends, leather, suede, and embellished fabrics should be handled by a specialist.

How often should luxury garments be professionally cleaned?

After visible soiling, after intensive wear, or at the end of a season—particularly for coats, tailoring, and eveningwear.

Do you offer pickup and delivery in London?

Yes. Hampstead Garment Care offers pickup & delivery options across London (availability may vary by area).

✅ CTA Button Text Variations

- Book Luxury Clothing Care

- Get Expert Garment Cleaning

- Request Pickup & Delivery

- WhatsApp Our Specialists

- Visit Hampstead Garment Care

No comment