Why Luxury Clothing Requires Advanced Care – The Scientific Mechanisms Behind Fabric Degradation

Many consumers assume that high‑end garments naturally outlast their fast‑fashion counterparts. This is rarely true — and understanding why is central to Luxury Clothing Care London | Science Behind Fabric Damage | Hampstead Garment Care. In reality, luxury textiles possess — and therefore demand Luxury Clothing Care London | Science Behind Fabric Damage | Hampstead Garment Care levels of preservation — greater structural sensitivity, higher chemical reactivity, and significantly more complex fibre architectures than mass‑produced clothing. Their refinement is precisely what makes them vulnerable.

A £2,500 silk gown can suffer irreversible damage under the same laundering conditions that a £40 polyester dress tolerates with ease. This disparity is not a function of cost but of biomolecular composition, dye chemistry, and fibre‑engineering principles.

Luxury garments operate less like durable consumer goods and more like the kind of organic, reactive materials requiring Luxury Clothing Care London | Science Behind Fabric Damage | Hampstead Garment Care level protection — because their fibres respond dynamically to chemistry, heat, friction, and light. Organic, performance‑grade materials. They must be maintained with the same scientific caution used in textile conservation labs and museum preservation facilities.

At Hampstead Garment Care, our objective extends far beyond basic cleaning. As a leader in Luxury Clothing Care London, we integrate scientific preservation with couture‑level handling to slow degradation and protect every garment’s long‑term value. We aim to preserve the material integrity, craftsmanship, financial value, and cultural meaning embedded in each garment. Effective luxury care is not indulgence — it is required stewardship.

Luxury Clothing Care London | Science Behind Fabric Damage – The Scientific Basis of Luxury Fibre Behaviour

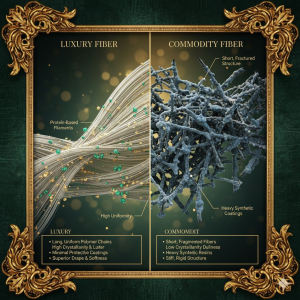

Luxury fibres differ from industrial textiles not only in feel and appearance but in the molecular physics that governs their performance. To expand on this, it helps to understand that fibres are essentially long chains of polymers — some natural, some engineered — whose behaviour is dictated by their molecular arrangement, crystallinity, cross‑linking, and interactions with water, pH, and mechanical force.

Luxury fibres differ from industrial textiles not only in feel and appearance but in the molecular physics that governs their performance. To expand on this, it helps to understand that fibres are essentially long chains of polymers — some natural, some engineered — whose behaviour is dictated by their molecular arrangement, crystallinity, cross‑linking, and interactions with water, pH, and mechanical force.

In luxury textiles, these polymer chains are often:

-

longer and more uniform, giving superior softness and drape;

-

less coated with synthetic resins, making them more breathable but less protected;

-

more crystalline or protein‑based, which improves lustre but increases reactivity;

-

sourced from biological systems, meaning they retain organic vulnerabilities.

Because of this, luxury garments do not merely “get dirty.” They undergo chemical, mechanical, and photonic degradation, similar to museum textiles or biological samples. Small changes in their environment can alter the molecular bonding inside fibres — sometimes permanently.

Below is an expanded explanation of how each environmental factor affects luxury fibres:

Luxury fibres do not behave like simple industrial materials. Instead, they function much closer to biological systems — dynamic, reactive, and deeply influenced by the environments they encounter. Principles of fibre chemistry, polymer science, and molecular structure govern their performance.

At a microscopic level, luxury textiles contain fewer impurities, longer or more uniform molecular chains, and more delicate crystalline or protein-based structures. This structural purity is what gives them their superior softness, sheen, drape, and responsiveness to movement. However, purity also means vulnerability: anything that alters these molecular arrangements can cause rapid degradation.

Because luxury fibres are made from natural polymers (like cellulose or keratin) or delicate engineered long-staple structures, they react to physical and chemical stimuli the way organic matter does. They expand, contract, weaken, swell, oxidise, and even chemically bond with substances in their environment.

Specifically, these fibres respond dynamically to:

-

Temperature can alter hydrogen bonding, disrupt crystalline regions, or denature proteins.

-

pH changes, which can break down natural dyes, weaken polymer chains, or dissolve protective surface layers.

-

Moisture, which causes swelling, shape distortion, or increases dye migration.

-

Mechanical friction, which physically abrades fibres, disrupts surface cuticles, and accelerates wear.

-

UV exposure triggers photo-oxidation and breaks chemical bonds.

In short, the very qualities that make luxury fabrics beautiful — long fibres, natural dyes, minimal chemical coatings, high purity — also make them highly susceptible to scientific forms of damage that rarely affect mass‑produced synthetics.

Understanding these mechanisms is essential for preserving garment longevity and achieving truly effective outcomes in luxury clothing care, which is why luxury clothing care requires a conservation‑grade approach rather than standard laundry methods.

Silk – A Crystalline Protein with High Reactivity | Luxury Clothing Care London

Silk is composed of fibroin, a crystalline protein extruded by silkworms. Its layered molecular architecture refracts light, producing the characteristic lustre. However, the protein structure is vulnerable to alterations induced by:

-

Temperatures exceeding ~30°C disrupt hydrogen bonding between protein chains.

-

Alkaline detergents, which hydrolyse surface proteins and destabilise the fibre.

-

Mechanical abrasion, resulting in microscarring visible under magnification.

-

Photo‑oxidation, which breaks peptide bonds and causes yellowing.

A spill containing sugars — such as champagne — may appear benign initially. Over time, oxidation transforms these sugars into chromophores, creating stains that cannot be reversed without specialised chemical intervention.

At Hampstead Garment Care, silk is processed using our Luxury Clothing Care London | Science Behind Fabric Damage | Hampstead Garment Care protocols under controlled pH, minimal mechanical stress, low‑mineral water conditions, and calibrated humidity, mirroring conservation‑grade protocols.

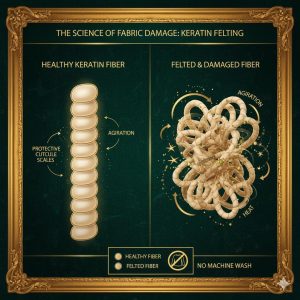

Wool, Cashmere, and Camel Hair – Keratin‑Based Fibres with Structural Vulnerability | Luxury Clothing Care London

Luxury animal fibres are composed of keratin, a protein that forms coiled‑coil helices surrounded by overlapping cuticle layers. These fibres behave as micro‑springs, providing softness and elasticity — but only under the right conditions.

Luxury animal fibres are composed of keratin, a protein that forms coiled‑coil helices surrounded by overlapping cuticle layers. These fibres behave as micro‑springs, providing softness and elasticity — but only under the right conditions.

Damage occurs through:

-

Excess heat denatures keratin proteins.

-

Agitation, which interlocks cuticles, results in felting and shrinkage.

-

High‑alkaline detergents erode the protective cuticle barrier.

For this reason, even a “delicate” machine cycle can distort or shrink a luxury cashmere garment. Cashmere is not weak; rather, it is chemically and mechanically sensitive, requiring a non‑rotational, immersion‑based approach.

Luxury Cotton vs. Commodity Cotton – Fibre Length and Structural Risk | Luxury Clothing Care London

Commodity cotton consists of short staples that tolerate force and friction at the cost of softness. By contrast, Egyptian and Pima cottons have long, acceptable staples that produce exceptional smoothness and breathability.

However, long fibres are more prone to:

-

Breakage from mineral‑rich hard water, common in London.

-

High‑spin cycles, which introduce torsional stress.

-

Tumble‑dry heat, which collapses fibre morphology.

A luxury cotton shirt that initially feels silky can quickly harden and lose structure when laundered under standard home conditions.

At Hampstead Garment Care, we employ water‑softening, pH stabilisation, controlled finishing, and artisanal pressing techniques influenced by Savile Row standards.

Why Luxury Garments Degrade Faster Than Mass‑Produced Clothing | Luxury Clothing Care London

The paradox of luxury fashion is that the very qualities that make these garments exceptional — their softness, luminosity, fluidity, and craftsmanship — also make them structurally fragile. In other words, luxury does not equal durability. It equals refinement, and refinement requires protection.

From a textile‑science perspective, luxury garments degrade more quickly because they are engineered for aesthetic performance rather than industrial durability. To understand this more deeply, consider the following structural and chemical factors:

1. Ultra‑Fine Fibres = Higher Surface Area Exposure

Luxury garments are often made from wonderful fibres — long‑staple cotton, Grade‑A cashmere, mulberry silk, superfine merino. These fibres have diameters measured in microns, meaning each strand has a much higher surface‑area‑to‑mass ratio compared to thicker synthetic fibres. This microscopic fineness produces:

-

Softer handle (because fibres bend easily and sit smoothly against the skin)

-

Better drape (due to low stiffness and high flexibility)

-

Superior visual quality (light interacts more delicately with fine fibres)

However, the same fineness also introduces structural vulnerability. Ultra‑fine fibres have less internal volume and fewer polymer chains within each cross‑section. As a result, they:

-

Abrade faster — there is less material to buffer against friction before structural breakdown occurs.

-

Break more easily — fine fibres require less force to reach their tensile failure point.

-

Absorb chemicals more deeply — their small diameters allow liquids, sweat, and contaminants to penetrate quickly into inner molecular layers.

-

Lose elasticity sooner under stress — repeated stretching fatigues their long-chain polymers more rapidly.

Luxury fibres also lack the protective coatings commonly applied to synthetics. Polyester, nylon, and acrylic are often engineered with:

-

Surface resins

-

Anti‑pilling treatments

-

Hydrophobic coatings

-

Thermo‑set bonding

These coatings act like armour, allowing synthetic fibres to resist deformation, abrasion, moisture, and chemical exposure.

In contrast, natural luxury fibres remain untreated by design — to preserve their softness, purity, and movement — leaving them exposed to environmental stressors at the molecular level.

2. High‑Drape Fabrics Sacrifice Stability

The fluid movement of silk, cashmere, and high‑end viscose is the direct result of low internal friction between polymer chains. In simpler terms, the fibres slide past each other with minimal resistance, which gives these fabrics their beautiful flow, softness, and elegance.

But scientifically, this low friction also means low structural rigidity. When fibres do not resist movement, they also do not resist deformation. This creates several forms of instability:

-

Stretching under tension – Because fibres glide so easily, they elongate quickly when pulled, even by their own weight.

-

Humidity‑driven distortion – Moisture causes fibre swelling, relaxing internal bonding and warping the drape.

-

Loss of structural memory – With fewer internal cross-links and weak inter-fibre resistance, the fabric cannot spring back to its original shape.

-

Panel distortion in garments – Bias‑cut pieces and delicate weaves shift over time, leading to twisting seams and asymmetry.

-

Hanger deformation – Gravity pulls on the fabric, causing shoulder points, sleeve heads, and hems to stretch irregularly.

At a molecular level, high‑drape luxury textiles:

-

Contain long, smooth polymer chains with minimal crystalline regions (making them flexible but unstable).

-

Have a low elastic modulus, meaning they stretch much less than synthetic fabrics.

-

Possess low torsional rigidity, so the fibres rotate and twist under tiny forces.

This softness is intentional — it is what gives silk its “liquid” quality and cashmere its cloud‑like movement. But it comes at a cost.

Luxury drape is achieved only by compromising mechanical stability. These fabrics are meant to be worn gently, shaped carefully, cleaned professionally, and stored thoughtfully to prevent long‑term distortion.

3. Natural Dye Systems Are Chemically Reactive

Luxury brands frequently use:

-

Botanical dyes

-

Low‑impact dyes

-

Artisanal dye techniques

-

Hand‑pigmented or small‑batch treatments

These dyes are prized for their ability to produce depth, nuance, and tonal richness that synthetic dyes cannot replicate. However, they are also chemically fragile. Unlike industrial dyes, which are engineered to bind tightly and remain stable under stress, natural dye systems rely on weak molecular interactions, such as hydrogen bonding and Van der Waals forces.

This fragility makes them vulnerable to a wide range of everyday exposures:

-

Sweat (acidic pH) – disrupts dye–fibre bonding, causing colour migration and fibre thinning.

-

Deodorant (alkaline + aluminium salts) – triggers chemical reactions that produce permanent yellow or brown patches.

-

UV light – breaks chromophores within dyes, causing rapid fading and instability.

-

Perfume (alcohol) – dissolves surface‑level pigments and accelerates oxidation.

-

Skin oils & cosmetics – act as solvents, weakening the adhesion of dyes.

These reactions lead to visible and long‑term effects:

-

Underarm discolouration – caused by pH shifts and aluminium‑dye interaction.

-

Fading – due to photo‑oxidation and dye molecule breakdown.

-

Yellowing – from oxidised sugars, oils, and unstable dye bonds.

-

Fibre weakening – as dye loss exposes vulnerable fibre surfaces.

From a chemical standpoint, natural dyes lack the molecular reinforcement found in synthetic dye systems. Mass‑produced garments typically use reactive dyes or disperse dyes engineered to:

-

form strong covalent bonds with fibres,

-

resist pH shifts,

-

withstand UV exposure,

-

repel alcohol and oils.

In synthetic textiles, these dye molecules are designed using principles of polymer chemistry and materials engineering. Reactive dyes, for example, form true chemical bonds with cellulose fibres — meaning the dye molecule becomes part of the fibre itself. Disperse dyes used on synthetics like polyester are formulated to sit deep inside the fibre’s hydrophobic regions, making them exceptionally resistant to environmental stress.

Natural dyes, by contrast, attach to fibres through weak physical interactions — hydrogen bonds, ionic attraction, and Van der Waals forces. These interactions are easily disrupted by:

-

pH changes (especially sweat acidity and deodorant alkalinity),

-

heat and humidity,

-

UV exposure,

-

alcohol from perfume,

-

oils and sebum from skin contact.

Because natural dyes sit closer to the fibre surface, they also undergo rapid photo‑oxidation, where UV light breaks the chromophore structures responsible for colour. This leads to fading, patchiness, yellowing, and weakening of the surrounding fibre.

Synthetic dyes are essentially engineered for stability, while natural dye systems trade durability for rich, organic visual complexity. This means synthetic dyes are designed to be durable. In contrast, natural dye systems are intended for beauty — and beauty, in this case, is inherently more delicate, more reactive, and more prone to long‑term molecular degradation.

4. Lightweight Interlinings & Minimal Reinforcement

High‑end garments intentionally avoid the heavy, rigid interfacings commonly found in mass‑produced clothing because these stiff components interfere with the garment’s natural movement, breathability, and drape. In couture and luxury tailoring, designers prioritise fluidity, comfort, and anatomical shaping, which require construction techniques fundamentally different from those of industrial fashion.

Couture garments may have:

-

Hand‑stitched interlinings — allowing the garment to move with the body rather than against it.

-

No bonding adhesives — preserving fibre purity and preventing heat‑activated glue from stiffening delicate fabrics.

-

Minimal structural padding — ensuring softness, flexibility, and a more natural silhouette.

These practices honour tradition and craftsmanship, but they also create structural vulnerabilities. By removing industrial reinforcements, the garment becomes far more sensitive to environmental and mechanical stress. This reduced reinforcement increases susceptibility to:

-

Tension from wear — seams and panels can stretch, distort, or lose shape because they lack rigid internal support.

-

High heat — delicate interlinings and natural fibres deform quickly under pressing or accidental exposure to radiators or hot storage areas.

-

Mechanical force — pulling, rubbing, or mishandling the garment can easily disrupt the internal structure, causing puckering, fabric separation, or collapse of the intended silhouette.

From a textile‑science perspective, traditional interfacings use fusible polymers that melt and bond to the fashion fabric, creating a stable composite structure. Luxury garments reject this process because high heat and adhesive resins can:

-

flatten or scorch silk,

-

stiffen soft fibres like cashmere,

-

cause bubbling occurs as adhesives age,

-

interfere with breathability and drape.

Instead, couture garments rely on natural-fibre canvas, horsehair, or cotton batiste, which are hand‑anchored with micro‑stitches. These materials provide subtle shaping but do not offer the mechanical stability of bonded synthetics.

As a result:

-

The garment’s shape is more dependent on the integrity of the outer fabric.

-

The interlining can shift slightly during wear, requiring careful pressing to realign.

-

Humidity and body heat soften the internal layers, making the garment prone to distortion.

A polyester blazer has rigid, industrial interlinings engineered for durability, uniformity, and mass‑production efficiency. A silk blazer, however, has delicate, breathable, hand‑crafted components designed for elegance — not endurance — and the difference becomes obvious with wear, cleaning, and time.

This is why luxury tailoring must be handled with conservation‑level precision: the internal architecture is artistic rather than industrial, and therefore significantly more vulnerable to damage.

5. Chemical Exposure Has a Greater Impact on Natural Fibres

Natural fibres such as keratin (wool, cashmere), cellulose (cotton, viscose), and fibroin (silk) are fundamentally reactive polymers. Their molecular structures contain active sites — amino groups, hydroxyl groups, peptide bonds — that readily interact with chemicals in their environment. This sensitivity means that even minor exposures can trigger significant structural and visual changes.

These fibres form chemical bonds that are easily disrupted by:

-

pH imbalance – Acidic or alkaline exposure breaks hydrogen bonds and weakens polymer chains.

-

Oxidation – Oxygen reacts with amino acids and cellulose, causing yellowing, brittleness, and dye fading.

-

Alcohol – Found in perfumes and some skincare products; dissolves natural oils and destabilises surface dyes.

-

Mineral deposits – Hard water minerals (calcium, magnesium) attach to fibres, making them stiff, dull, and prone to breakage.

-

Body oils – Lipids penetrate the fibre core, causing oxidation, darkening, and degradation over time.

-

Cosmetic residues – Sunscreen, foundation, deodorant, and hair products contain reactive chemicals (such as titanium dioxide, zinc oxide, and aluminium salts) that can cause long-term staining and fibre weakening.

At the molecular level, natural fibres behave like open, absorbent networks. Their polymer chains allow moisture, oils, and chemicals to diffuse into internal regions, where they can disrupt the structure and dye molecules. Once these reactions occur deep inside the fibre, the damage becomes permanent.

Synthetic fibres, by contrast, are:

-

hydrophobic, meaning they repel moisture and oils;

-

chemically inert, with few reactive sites available for oxidation or pH damage;

-

protected by engineered surface coatings, which act as barriers;

-

non‑absorbent, preventing substances from penetrating the fibre core.

This makes synthetic fibres extremely resistant to chemical interactions that would quickly damage natural materials.

In luxury textiles, chemical exposure leads to:

-

colour loss and dye migration, due to broken dye–fibre bonds;

-

yellowing and brown spotting, caused by oxidised oils and sugars;

-

loss of tensile strength, as chemical reactions break internal bonds;

-

texture changes, including stiffness, roughness, and uneven hand-feel.

Because natural fibres readily absorb and react with their surroundings, even invisible chemical exposures accumulate over time — which is why luxury garments can degrade significantly between wears, not just during washing.

6. Fibre Fatigue Occurs Significantly Faster in Luxury Textiles

Repeated stress — even mild — causes luxury fibres to undergo progressive, microscopic structural failure known as fibre fatigue. Unlike synthetic fibres, which are engineered to withstand high mechanical stress, natural luxury fibres break down quickly when exposed to friction, stretching, heat, or rotational movement.

From a materials‑science perspective, fibre fatigue involves several interconnected processes:

-

Micro‑fractures — Small cracks form within the fibre’s polymer chains. Over time, these cracks propagate, weakening the entire structure.

-

Loss of elasticity — Repeated stretching causes permanent deformation. Polymer chains lose their ability to return to their original length, resulting in sagging, distortion, or thinning.

-

Surface roughening — The outer layers of the fibre become worn, fuzzy, or prone to pills. This not only affects appearance but also accelerates further mechanical damage.

-

Weakened dye bonds — When the fibre structure destabilises, dye molecules are no longer held tightly. This leads to fading, patchiness, or colour bleeding.

At a molecular level, silk, cashmere, and long‑staple cotton possess long, delicate polymer chains. These chains are easily disrupted by rotational washing, heat exposure, mechanical agitation, or repeated bending — even when not visible to the naked eye.

The collapse of these internal structures happens quickly. A garment may look fine on the surface, yet under magnification, the fibres show early signs of collapse long before visible damage appears. This is why luxury items seem to “suddenly” lose shape or softness — the breakdown has been accumulating silently.

By comparison, synthetic fibres such as polyester or nylon have:

-

engineered cross‑linking systems,

-

superior tensile strength,

-

surface coatings that reduce abrasion,

-

hydrophobic properties that resist swelling,

-

and uniform filament surfaces designed to resist fracturing.

These fibres can endure dozens of aggressive wash cycles because they are chemically stabilised and mechanically reinforced.

Luxury fibres are the opposite. They are not engineered for survival — they are engineered for beauty, softness, movement, breathability, and natural handle. And because of this, even slight deviations from safe care practices — a too‑hot wash, a high‑spin cycle, a rough detergent, a bit of friction — accelerate fibre fatigue dramatically.

In summary, luxury garments degrade faster because they prioritise aesthetics, purity, and craftsmanship over mechanical durability, which is precisely why Luxury Clothing Care London | Science Behind Fabric Damage | Hampstead Garment Care is essential for long‑term preservation. Their fibres are refined, their dyes are reactive, and their construction is delicate — and that is what makes professional care essential.

Hidden Mechanisms of Designer Garment Damage | Luxury Clothing Care London

1. pH Variability (Sweat‑Induced Chemical Reactions)

Human sweat is mildly acidic (typically pH 4–6), and this slight deviation from neutrality is chemically significant for luxury fabrics. Many luxury dyes — especially natural, plant‑based, artisanal, or low‑impact dyes — lack robust pH stability. These dyes rely on weak ionic and hydrogen bonding rather than strong covalent attachment. Even slight changes in acidity can weaken or disrupt these bonds entirely.

Beyond the visible staining, sweat triggers a cascade of underlying reactions:

-

Dye–fibre bond disruption – Acidic sweat destabilises delicate dye molecules, causing them to detach from the fibre and migrate.

-

Hydrolysis of protein fibres – In silk or cashmere, excess acidity begins to break peptide bonds, weakening the fibre at a molecular level.

-

Metallic salt reactions – Aluminium found in many deodorants reacts with sweat and dyes, forming insoluble compounds that cause deep‑set yellow or brown staining.

-

Crystallisation of sweat salts – As sweat dries, salts crystallise inside the fibre, creating stiffness, abrasion points, and long‑term weakening.

-

Increased bacterial activity – Sweat provides moisture and nutrients for bacteria, whose metabolic byproducts further degrade fibres and dyes.

These processes manifest visually as:

-

Discolouration in the underarm region

-

Fibre weakening and thinning

-

Textural stiffness or rough patches

-

Progressive fading or patchiness

Critically, these reactions begin long before any visible signs appear. By the time yellowing or fading becomes noticeable, the underlying chemical damage has usually been occurring for weeks or months — often deep inside the fibre where home cleaning cannot reach.

This is why professional pH‑controlled cleaning is essential for luxury garments exposed to perspiration.

2. Microscopic Abrasion During Laundering

Even on low‑agitation cycles, garments collide with the drum, zips, and seams. Under a microscope, affected fibres often resemble scorched or frayed filaments, indicating cumulative mechanical fatigue.

3. Oxidative Staining

Substances such as wine, perfume, sunscreen, or citrus residues undergo oxidation, shifting from invisible to visibly yellow‑brown as oxygen interacts with them.

Customers often believe stains appear “suddenly,” when they are in fact observing the final stage of a long chemical process.

4. Ultraviolet Degradation

UV radiation does far more than cause fabrics to fade — it initiates a series of photochemical reactions that break down the molecular structure of natural fibres. Unlike synthetic fibres, which are engineered with stabilisers, natural luxury fibres lack UV‑resistant additives and are therefore highly vulnerable.

When exposed to sunlight or artificial UV sources, fibres undergo:

-

Photo‑oxidation – UV light breaks chemical bonds within cellulose (cotton), fibroin (silk), and keratin (wool/cashmere), creating free radicals that weaken the fibre.

-

Chromophore degradation – The colour‑producing molecules within dyes are destroyed, leading to fading and uneven colour patches.

-

Polymer chain scission – UV radiation cleaves long polymer chains into shorter fragments, which dramatically reduces tensile strength.

-

Surface embrittlement – The fibre exterior becomes dry, brittle, and prone to cracking.

In practical terms, UV damage appears as:

-

Yellowing – due to oxidation of natural oils and amino acids.

-

Fading – especially in naturally dyed or dark garments.

-

Brittleness – fibres snap more easily under stress.

-

Patchy weakening – areas exposed to more light degrade faster, causing uneven wear.

Even short periods of sunlight exposure — such as hanging a silk blouse near a window — can cause measurable deterioration. For this reason, luxury garments should always be stored away from direct light, covered with breathable, UV‑blocking garment bags.

5. Compression and Overcrowding

Tightly packed wardrobes may seem harmless, but sustained pressure and friction can cause gradual mechanical deformation of delicate fabrics. When garments are squeezed together:

-

Fibres rub against neighbouring textiles, creating micro‑abrasion.

-

Weaves become compressed, flattening the surface texture and reducing drape quality.

-

Shoulder points and sleeve heads deform, especially in knitwear and tailored garments.

-

Natural fibres lose shape memory, leading to permanent distortion.

-

Delicate embellishments or beadwork become crushed, damaging couture details.

Overcrowding also traps humidity, creating the perfect environment for:

-

mildew growth, especially on protein fibres;

-

dye migration, where colours transfer between garments;

-

odour absorption, as natural fibres absorb environmental smells.

For long‑term preservation, luxury garments require space, ventilation, and structural support. Using padded hangers, breathable covers, and ensuring garments have room to “breathe” dramatically extends fibre life and maintains garment architecture.

Five Common Household Practices That Damage Luxury Garments

-

Machine‑washing cashmere, even on “delicate,” causes rotational stress.

-

Applying fragrance directly to fabric, allowing alcohol to burn protein‑based fibres.

-

Hanging heavy knitwear, leading to irreversible stretching.

-

Scrubbing stains, which embed pigments deeper and fracture fibres.

-

Drying garments near heat sources destabilises the structures of wool, silk, and premium cotton.

Additionally, most supermarket detergents are highly alkaline and unsuitable for delicate fibre systems.

How Hampstead Garment Care Applies Scientific Textile Preservation | Luxury Clothing Care London

We operate as a textile conservation and fibre‑science facility, not merely as a dry‑cleaning service. Our processes mirror the methodologies used in museum conservation labs, where garments are treated as cultural artefacts rather than consumer items. Every step is built around minimising fibre stress, preventing molecular degradation, and extending long‑term textile stability.

Fibre Identification and pH Analysis

Each garment undergoes a multi‑stage diagnostic evaluation that allows us to map its vulnerabilities before any cleaning begins.

1. Fibre Classification (Protein, Cellulose, Blends)

We determine the exact fibre composition using microscopic examination and burn‑test indicators. Understanding the fibre type is critical because:

-

Protein fibres (silk, wool, cashmere) denature under heat and alkaline exposure.

-

Cellulose fibres (cotton, viscose) swell in water and react to acidity.

-

Blends require carefully balanced chemistry to avoid weakening the more fragile component.

This classification ensures we never expose a fibre to a solvent, temperature, or mechanical action it cannot safely tolerate.

2. pH Testing

Every fibre has a safe pH range. Even minor deviations can cause:

-

surface erosion,

-

dye loss,

-

structural weakening,

-

and long‑term brittleness.

But pH sensitivity extends far beyond surface effects. The internal chemistry of natural fibres is built on delicate balances of hydrogen bonding, ionic charge, peptide stability, and crystalline alignment. When the pH shifts — even slightly — those internal structures begin to unravel.

How pH chemically affects different luxury fibres:

-

Silk (fibroin) – low alkalinity breaks peptide bonds, causing thinning and loss of lustre.

-

Wool & cashmere (keratin) – alkalinity lifts the cuticle scales, causing felting; acidity weakens disulfide bonds.

-

Luxury cotton (cellulose) – acidity hydrolyses cellulose chains; alkalinity disrupts hydrogen bonding and increases brittleness.

Why pH fluctuations occur:

-

Sweat (acidic)

-

Deodorant (alkaline + aluminium salts)

-

Skincare residues (varied pH)

-

Hard water (alkaline mineral content)

-

Incorrect detergents (usually alkaline)

When these substances are absorbed into fibres, they shift the pH micro-environment — often permanently.

Our process: We measure the garment’s current pH state — not only overall, but in micro‑zones where sweat, deodorant, makeup, or perfume have accumulated. These areas can be several pH points more acidic or alkaline than the rest of the fabric.

Once mapped, we adjust our cleaning chemistry using:

-

buffer baths to stabilise the fibre environment,

-

acid‑neutralising rinses for alkaline‑damaged fibres,

-

restorative protein conditioners for silk and wool,

-

chelating agents to remove pH‑altering minerals.

This ensures the fibre is returned to its neutral, stable state — restoring internal balance, reducing long‑term degradation, and protecting the garment’s structural integrity far beyond what ordinary cleaning methods can achieve.

3. Dye‑Fastness Assessment

We conduct controlled spot‑tests using micro‑droplets and blot‑film analysis to determine whether dyes are:

-

reactive,

-

disperse,

-

vat‑dyed,

-

or naturally bonded.

This step reveals how easily the dyes will bleed or fade. If a garment shows low dye stability, we apply fixatives, barriers, or solvent‑free methods to prevent migration.

4. Water Mineral Interaction Analysis

London’s water contains high levels of calcium and magnesium, which can:

-

harden fibres,

-

cause greying of whites,

-

and leave microscopic mineral deposits.

We test how the garment’s fibres interact with mineralised water and adjust by using softened water, chelating agents, or deionised rinses to prevent mineral bonding.

This science‑based evaluation enables a tailored cleaning methodology specifically engineered to minimise fibre stress at every stage, protecting both structural integrity and aesthetic finish.

Precision Stain Removal

Our approach emphasises micro‑scale intervention using:

-

Pipettes for controlled reagent application

-

Scalpels for removing oxidised residues

-

Micro‑steam technology for loosening particles

-

Zero mechanical abrasion

High‑Temperature Steam Finishing

Steam at ~180°C reshapes fibres while avoiding compression damage common in flat pressing.

Protective, Controlled Handling

Garments are kept away from raw machinery and handled with:

-

Cushioned supports — preventing point‑pressure, fibre compression, and seam stress during all stages of cleaning and finishing.

-

Padded hangers — shaped to maintain shoulder architecture, distribute garment weight evenly, and protect tailoring canvases and knitwear structures.

-

Museum‑grade wrapping materials — acid‑free tissue, inert polyethene covers, and breathable archival sheeting that prevent oxidation, dye migration, humidity damage, and UV exposure.

-

Gentle, gloved handling — reducing friction and preventing oil transfer from hands, which can oxidise delicate fibres.

-

Isolated workflow zones — ensuring garments never brush against industrial equipment, zippers, metal surfaces, or abrasive components.

-

Low‑tension suspension and drying frames — used to support garments in their natural shape, preventing gravitational distortion or stretching.

This process reflects conservation‑standard textile treatment, ensuring each garment is protected from mechanical stress, chemical contamination, and environmental factors throughout the entire preservation journey.

Luxury Garments as Long‑Term Assets | Luxury Clothing Care London

Luxury fashion retains cultural, aesthetic, and monetary value when properly maintained. These garments are more than fabric — they function as financial assets, cultural artefacts, and long-term investments in craftsmanship. When preserved correctly, luxury textiles appreciate, retain structural integrity, and carry emotional and historical significance.

-

A Dior silk blouse maintains resale value because well-preserved silk retains lustre, stability, and rarity appeal.

-

A Loro Piana coat may last decades due to its exceptionally long cashmere fibres — but only if protected from pH shifts, friction, and UV exposure.

-

A bespoke suit can endure generational use because hand‑stitched canvases and natural fibres age gracefully when cleaned and stored under controlled conditions.

From a materials‑science standpoint, luxury garments deteriorate fastest when subjected to home laundering because improper cleaning causes:

-

40–60% reduction in fibre lifespan through repeated mechanical abrasion.

-

Accelerated dye loss, especially in hand‑dyed or naturally pigmented textiles.

-

Structural collapse in canvassing, interlinings, and delicate stitching.

-

Protein denaturation in silk and cashmere due to heat and alkalinity.

-

Permanent oxidation of invisible residues left untreated.

When professionally cared for, however, these garments not only survive — they retain value, preserve their aesthetic qualities, and extend their usable lifespan by decades.

Luxury clothing is not inherently costly — but without Luxury Clothing Care London | Science Behind Fabric Damage | Hampstead Garment Care, the damage becomes costly — inadequate care is what makes luxury expensive. Investing in proper cleaning, storage, and preservation ensures that each garment remains a long‑term asset rather than a short‑term purchase.**

Call to Action | Luxury Clothing Care London

Book a collection today.

WhatsApp: 07859 810207

Free stain assessment available.

Specialised care for silk, cashmere, couture, and designer tailoring.

Eco‑friendly textile preservation services in Hampstead and Central London.

Hampstead Garment Care

Where scientific preservation meets craftsmanship — and where Luxury Clothing Care London is elevated to a conservation‑grade standard.

Internal Links | Luxury Clothing Care London

FAQ | Luxury Clothing Care London

Q1: Why is luxury clothing more sensitive than regular clothing?

Luxury fibres have longer polymer chains, natural dyes, and minimal protective coatings, making them reactive to pH, heat, UV, and abrasion.

Q2: Can I wash silk or cashmere at home?

Home washing destabilises protein structures and causes fibre fatigue. Luxury fibres require controlled pH, soft‑water systems, and zero‑agitation handling.

Q3: Why do designer garments discolour under the arms?

Sweat acidity + deodorant aluminium salts trigger dye breakdown and fibre hydrolysis — a chemical reaction prevented only by professional pH‑neutral cleaning.

Q4: What makes professional luxury care better than regular dry cleaning?

We use conservation‑grade chemistry, micro‑steam stain removal, mineral‑controlled water, and fibre‑specific diagnostics.

Q5: Does luxury clothing hold financial value?

Yes — when preserved with scientific care, luxury pieces maintain their resale value and last for decades.

No comment